Exploring Cosmetic Powder Compact Molds

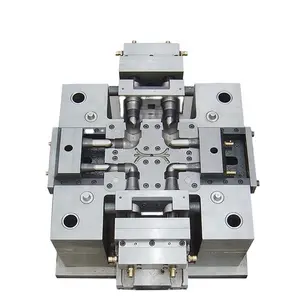

The realm of beauty and cosmetics is ever-evolving, with cosmetic powder compact molds playing a pivotal role in the packaging and presentation of cosmetic products. These molds are essential for creating the precise and durable cases that house various makeup items, ensuring they are both functional and aesthetically pleasing.

Types and Applications

Cosmetic powder compact molds come in various types, each designed to cater to different packaging needs. From classic clamshell designs to intricate shapes for eye-catching presentations, these molds are utilized to create containers for products such as eyeshadows, blushes, and foundation powders. Their applications extend to personal care and beauty industries, where the demand for innovative and sustainable packaging solutions is continuously rising.

Material and Design Features

The materials used in cosmetic compact mold manufacturing are chosen for their durability and quality. Common materials include plastics that are eco-friendly, promoting sustainability in the cosmetics industry. The design features of these molds are critical, as they must ensure the ease of use and portability. Lightweight and handmade options are available, catering to the diverse preferences of the beauty market.

Advantages of Quality Molds

Investing in high-grade cosmetic powder compact molds offers numerous advantages. These molds are designed to be eco-friendly, reducing the environmental impact of cosmetic packaging. Additionally, the precision of these molds ensures a snug fit for the cosmetic product, protecting it from damage and contamination. The aesthetic appeal of well-crafted molds can also enhance the overall brand image, making the product more attractive to consumers.

Customization and Finishing Techniques

Customization is a key aspect of cosmetic powder compact mold production. Molds can be tailored to specific design requirements, including unique shapes and sizes. Finishing techniques such as UV coating or glossy lamination can be applied to the final product, providing an additional layer of protection and a premium finish.

Choosing the Right Supplier

Selecting the appropriate supplier for cosmetic powder compact molds is crucial. It is important to consider the supplier's capability to provide a variety of options and their commitment to eco-friendly practices. While Alibaba.com does not endorse any specific suppliers, the platform facilitates connections between buyers and a diverse range of experienced suppliers in the cosmetic packaging industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4