Introduction to Delta Wood Pallet Making Machines

The delta wood pallet making machine stands as a cornerstone in the woodworking industry, providing an essential solution for producing sturdy and reliable wood pallets. This category encompasses a variety of machines designed to meet the diverse needs of pallet production, from small-scale operations to large-scale manufacturers.

Types and Applications

There are several types of wood pallet machinery tailored to different production volumes and specifications. These machines are utilized in creating pallets that serve as a base for storing, assembling, and transporting goods. Their applications span across various industries, including logistics, warehousing, and supply chain management, making them indispensable in the global market.

Features and Materials

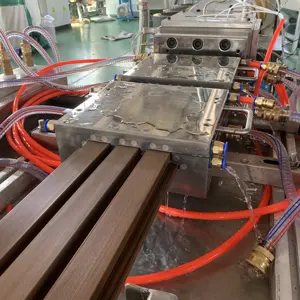

A pallet manufacturing machine is engineered to work with a range of materials, primarily wood varieties suitable for heavy-duty use. These machines boast features that enhance efficiency, such as adjustable pallet sizes, automated nailers, and high-precision cutting tools, ensuring that each pallet meets industry standards and requirements.

Advantages of Modern Machinery

Modern pallet making equipment offers numerous advantages, including increased production speed, uniform product quality, and reduced labor costs. These machines are designed for ease of operation and are capable of producing pallets that meet exact specifications with minimal waste, contributing to a more sustainable production process.

Choosing the Right Machine

Selecting the appropriate wood pallet machine is crucial for any business in the field. Factors to consider include the machine's capacity, the size and design of pallets needed, and the type of wood used. It's important to assess the range of machines available to ensure the chosen equipment aligns with the specific production goals and operational scale.

Maintenance and Safety

Maintaining a wood pallet production machine is vital for its longevity and performance. Regular cleaning and adherence to maintenance schedules prevent downtime and extend the life of the machinery. Safety is paramount; thus, operators should be well-trained to handle the equipment, ensuring a safe working environment.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4