Related Searches:

Top categories

About demister pad steam drum

Understanding Demister Pad Steam Drums

Demister pad steam drums are essential components in various industrial applications, designed to remove entrained liquid droplets from vapor streams. These devices ensure that only dry vapor exits the system, which is crucial for maintaining efficiency and protecting downstream equipment from corrosion and damage.

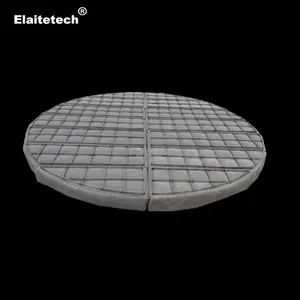

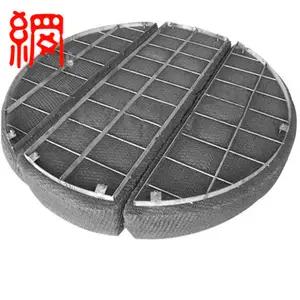

Types and Configurations

There are several types of demister pad steam drums to cater to different industrial needs. The selection typically depends on the operating conditions, such as vapor velocity, density, and viscosity. Mesh-type demisters, vane-type demisters, and fiber-bed demisters are among the common configurations, each with unique features to optimize separation efficiency.

Materials and Construction

The construction material of a demister pad is selected based on the chemical compatibility with the process fluid and the operating temperature. Materials range from metals like stainless steel to synthetic fibers, each offering distinct advantages in terms of durability and performance.

Applications Across Industries

Demister pads are utilized in a variety of sectors, including petrochemical, power generation, and food processing. Their primary role is to ensure process integrity by preventing liquid carryover, which can be critical in maintaining product purity and operational safety.

Features and Advantages

A steam drum demister is characterized by features such as high separation efficiency, low-pressure drop, and ease of installation. The advantages of incorporating these demisters include extended equipment lifespan, reduced maintenance costs, and improved product quality.

Choosing the Right Demister

Selecting the appropriate demister pad for steam drums involves considering factors such as the size of the drum, the nature of the vapor and liquid, and the desired efficiency. It is crucial to assess these parameters to ensure optimal performance and reliability of the demister within the system.