Popular in your industry

Top categories

About dip rubbers

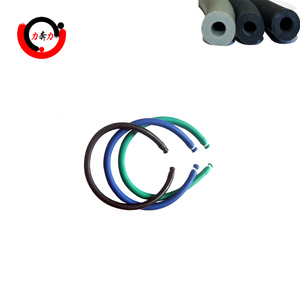

Dip Rubbers: An Overview

Dip rubbers, a versatile material in the industrial sector, are pivotal in the production of a myriad of products. This category encompasses a broad range of elastomeric compounds that are specifically designed for dip molding and coating applications. The unique properties of dip rubbers allow for the creation of items with varied levels of flexibility, durability, and resistance to environmental factors.

Types and Applications

The applications of dip rubbers are diverse, ranging from plasti dip painting to the manufacturing of protective coatings for automotive parts. In the realm of personal items, plasti dip shoe soles exemplify the adaptability of dip rubbers, providing enhanced grip and wear resistance. Industrial uses include forming seals and gaskets, essential for machinery and appliance integrity. The versatility extends to specialized applications such as plasti dip on eva foam for cosplay costumes, showcasing the material's ability to be tailored to niche markets.

Features and Materials

Dip rubbers are formulated to meet various industrial standards, ensuring resilience against oil, water, and temperature variations. The material's adaptability is evident in products like gun metal grey plasti dip, which not only offers aesthetic value but also maintains material integrity under stress. The elasticity of dip rubbers is a key feature, allowing materials like plasti dip aerosol spray to be stretched and reshaped without compromising their structure.

Advantages of Dip Rubbers

One of the primary advantages of dip rubbers is their tensile strength. They can endure significant stretching and manipulation, which is crucial for applications requiring a high degree of flexibility. This durability is particularly beneficial in the creation of weatherproofing materials, such as window strips that prevent leaks and drafts. Additionally, the ease of customization in color and form allows for a wide range of product design, from plasti dip red coatings to black plasti dip finishes.

Innovative Uses and Customization

Innovation in dip rubber technology has expanded its use to advanced fields, including aerospace and defense. The material's capacity to withstand extreme conditions makes it suitable for such demanding applications. For DIY enthusiasts, products like diy plasti dip car kits enable consumers to apply durable coatings themselves, illustrating the material's broad appeal and ease of use. The interval for plasti dip time between coats is optimized for efficiency, allowing for quick application and turnaround times.

Conclusion

Dip rubbers offer a flexible solution for a wide array of industrial and consumer needs. With the ability to be customized for specific uses, from aluminum plasti dip to decorative and protective coatings, dip rubbers remain an essential material in both production and innovative applications. The material's resilience and versatility make it a staple in various industries, underscoring its importance in modern manufacturing and design.