Exploring Double Injection Molding

Double injection molding, also known as double shot injection molding, is a sophisticated manufacturing process that combines two different materials or colors into a single end product. This technique is particularly beneficial for creating complex parts with multiple functionalities or aesthetic requirements. The process involves a double injection molding machine that injects two types of plastics into the same mold through separate channels, ensuring precision and efficiency.

Types and Applications of Double Shot Molding

The versatility of double shot molding extends to various industries, ranging from consumer electronics, where it's used for buttons with integrated symbols, to automotive applications for creating durable parts with a soft-touch surface. In the medical field, double color injection molding machines are instrumental in producing equipment with dual-material components, which can be critical for functionality and user comfort.

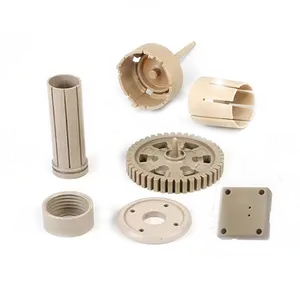

Features and Materials in Double Shot Injection Molding

Materials used in double shot injection are chosen based on their compatibility and the desired properties of the final product. Thermoplastics such as ABS, polycarbonate, and TPE are commonly used. The double injection molding process is designed to handle these materials with precision, ensuring that the bond between them is strong and the aesthetics are of high quality. The machines used are equipped with special screws that optimize plasticizing shot weight and speed, enhancing the molding capabilities.

Advantages of Double Shot Injection Molding Process

The double shot injection molding process offers numerous advantages, including the reduction of secondary processing by molding two materials simultaneously, which can lead to cost savings and increased production efficiency. The process also allows for the creation of parts with enhanced mechanical properties, such as improved impact resistance, and can eliminate the need for adhesives or connectors, which contributes to the durability and longevity of the product.

Technical Specifications of Double Shot Moulding Machines

Double shot moulding machines boast a clamping force that can vary significantly to accommodate different project requirements, ensuring that the exact clamping force needed is applied. These machines are engineered to resist external machining forces, and the steel bush in the clamping unit is designed to minimize wear resistance. This not only extends the life of the machine but also reduces maintenance costs associated with lubrication.

Choosing the Right Double Injection Molding Equipment

Selecting the appropriate double injection machine is crucial for achieving the desired product outcome. Prospective buyers should consider the specific requirements of their applications, such as the size of preforms and the type of materials to be used. Alibaba.com hosts a range of double barrel injection moulding machines from various wholesalers, allowing businesses to find the right equipment that fits their plastic processing needs without the concern of high defective rates.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4