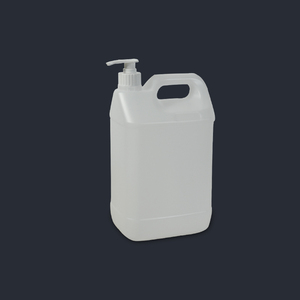

Barrel pumps are designed to fit into the opening of a barrel or drum, allowing for the easy transfer of liquids without the need to tip or move the heavy container. They come in various designs and can handle a wide range of fluids, from water and oils to more viscous or chemically aggressive liquids. The versatility and convenience of barrel pumps make them an indispensable tool in many sectors, including manufacturing, automotive, agriculture, food processing, and chemical handling. For more bulk options, browse Alibaba. com.

Types and Mechanisms of Barrel Pumps

Barrel pumps are available in several types, each suited to different applications and liquid properties. The most common types include manual pumps, electric pumps, and pneumatic (air-operated) pumps. Manual rain barrel pumps are operated by hand and are suitable for smaller volumes or where electricity is not available. Electric barrel pumps offer more power and are nice for transferring large volumes quickly. Pneumatic pumps are used in environments where electricity is hazardous or not available and are known for their durability and ability to handle a variety of liquids. The construction material of a barrel pump is chosen based on the type of liquid it will handle. For non-corrosive liquids like water or certain oils, plastic or aluminum pumps might be sufficient. However, for corrosive or hazardous liquids, pumps made of stainless steel, polypropylene, or other resistant materials are necessary to prevent contamination and ensure safety and longevity. The design of the pump also includes elements like seals and valves that are crucial for preventing leaks and ensuring efficient operation.

Barrel Pumps’ Safety and Efficiency in Handling Liquids

Safety is a nice consideration when using water barrel pumps, especially when handling hazardous or flammable liquids. Properly designed barrel pumps minimize the risk of spills and exposure, ensuring a safe transfer process. Moreover, they provide an efficient way to transfer liquids without the wastage and mess that can occur with manual pouring. Efficiency is crucial not only for maintaining a clean and safe working environment but also for reducing product loss and ensuring accurate dispensing.

Barrel Pumps' Maintenance and Care

Like any mechanical tool, water pumps for rain barrels require regular maintenance to ensure their longevity and proper functioning. This includes cleaning the pump after use, especially when handling different types of liquids, and checking for any signs of wear or damage, such as leaks or weak seals. Proper storage and regular inspection of the pump's components are essential to prevent breakdowns and ensure reliable operation.

In conclusion, air drum pumps are a vital tool for efficiently and safely transferring liquids in a variety of settings. Their range of designs and materials makes them suitable for handling a diverse array of liquids, from the most benign to the most hazardous. By selecting the appropriate type and material of pump for the specific liquid and application and by adhering to proper maintenance and safety practices, barrel pumps can significantly enhance the efficiency, safety, and cleanliness of liquid handling processes. Whether in an industrial plant, a farm, or a small workshop, a pneumatic drum pump is an invaluable asset for managing liquid storage and transfer effectively.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4