Popular in your industry

Related Searches:

Top categories

About e70b swing bearing

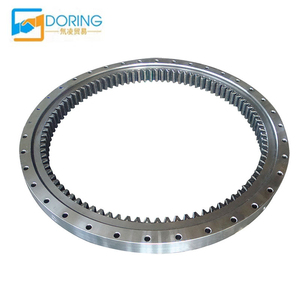

E70B Swing Bearing Overview

The e70b swing bearing is a pivotal component in heavy machinery, particularly in the construction and mining industries. This bearing facilitates the smooth rotation of the excavator's boom, allowing for precise maneuvering and operation. Its design caters to the demands of heavy loads and provides a reliable connection between the machine's undercarriage and upper structure.

Types and Applications

Diverse types of swing bearings exist to meet various operational requirements. The small slewing bearing is suited for lighter applications, whereas the large slewing bearings accommodate heavier tasks. Common applications include excavators, cranes, and turntables, where they manage axial, radial, and moment loads during rotation.

Features and Materials

Swing bearings are characterized by their robustness and durability. Materials such as alloy steel and hardened rolling elements are standard, ensuring the slewing ring drive withstands the rigors of heavy-duty use. The raceway surfaces are often gear-toothed, providing a drive mechanism that is integral to the slewing system.

Advantages of E70B Swing Bearings

The advantages of using a cross roller slewing bearing include improved equipment stability and extended service life. The design allows for simultaneous handling of complex loads, which is essential for the functionality of attachments requiring multidirectional movement.

Selection and Sourcing

Selecting the right slewing bearing for sale involves considering load capacity, size, and environmental conditions. Alibaba.com's platform enables buyers to connect with a global network of suppliers, ensuring a diverse selection to meet specific machinery requirements.

Maintenance and Care

Proper maintenance of the slewing ring bearing is crucial for optimal performance and longevity. Regular inspections and lubrication are recommended to prevent premature wear and potential equipment downtime.