Popular in your industry

Related Searches:

Top categories

About fiber sheets for roof

Selecting the right roofing material is a critical decision for any construction or renovation project. Fiber sheets have emerged as a popular choice due to their durability, versatility, and ease of installation. This article delves into the world of fibre cement sheets, a robust option that offers a blend of strength, moisture resistance, and environmental benefits, making them ideal for a range of buildings from agricultural to residential outbuildings. We'll explore the various types available on Alibaba.com, each with unique features to cater to different roofing needs, and provide insights into the factors that should guide your selection process for the optimal roofing solution.

Understanding Fiber Sheets for Roofing

Fibre cement sheets are a composite roofing material, consisting of Portland cement, sand, and cellulose fibers. These sheets are recognized for their adaptability and are commonly utilized in various buildings, including agricultural structures like barns and stables, as well as warehouses and residential outbuildings such as garages and sheds.

Their resistance to leaks and condensation makes them suitable for environments that require stable interior conditions, which is particularly important in agricultural settings where livestock is present. The material's ability to absorb and evaporate moisture helps to prevent the buildup of harmful bacteria and diseases.

Fibre cement roofing sheets stand out for their resilience against environmental factors. They are impervious to mould, rot, algae, and moss, and are also non-combustible and resistant to chemicals. Their dimensional stability under varying temperatures and immunity to rust contribute to their long lifespan, often exceeding several decades.

These sheets are also noted for their low maintenance requirements. Occasional cleaning with mild detergent or a power washer is sufficient to maintain their condition. Additionally, their breathable nature allows for enhanced airflow, making them an effective insulator and soundproofing material, while also being weatherproof.

The environmental impact of fibre cement sheets is relatively low due to the energy-efficient manufacturing process. At the end of their life cycle, they can be recycled, reducing waste. Aesthetically, they offer versatility with a range of color options to suit different project needs.

Types of Fiber Sheets Available on Alibaba.com

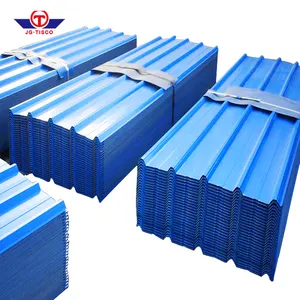

Alibaba.com offers a diverse range of fiber sheets for roofing, catering to various applications and preferences. Among the selection, customers can find PVC film galvanized steel zinc-coated sheets, known for their wavy corrugated structure that provides both aesthetic appeal and durability. For those prioritizing insulation, UPVC plastic PVC and polycarbonate translucent fiberglass options are available, which combine heat insulation properties with a translucent finish for natural lighting. Metal roofing enthusiasts have access to PPGI and PPGL tiles, featuring prepainted Galvalume corrugated steel with a selection of color coatings.

Fiberglass roofing sheets are also prominently featured, with offerings such as FRP tiles in customized colors and models, and clear translucent corrugated sheets that allow for ample daylight penetration. For environmentally conscious buyers, fibre cement roofing sheets are presented as a sustainable option, free from asbestos and boasting modern aesthetics. These sheets come in corrugated forms for added strength and flat versions for a sleek look. Additionally, Alibaba.com lists fiber-reinforced polymer plastic roof tile panels, known for their durability and lightweight properties.

The platform also caters to specialized needs with products like fiberglass wind guard boards, which serve as a barrier against noise while providing roofing protection. For those seeking a balance between toughness and aesthetic value, color-coated corrugated sheets made from carbon fiber reinforced UPVC are available. These sheets promise excellent toughness and strength, suitable for a variety of roofing projects. Each type of fiber sheet offers unique features and benefits, designed to meet the specific needs of diverse construction projects.

Factors to Consider When Selecting Fiber Sheets

When selecting fiber sheets for roofing, it's essential to consider their material composition and properties. The sheets should be composed of a resin matrix and carbon fiber reinforcement, ensuring a balance between strength and flexibility. The thickness of the sheets, which can vary, affects their tolerance and weight, and should be chosen based on the specific structural requirements of the roofing project.

Durability is another critical factor, with the sheets' ability to withstand different temperatures and environmental conditions being paramount. A high glass transition temperature (Tg) of around 80°C indicates the sheet's capacity to maintain structural integrity under heat. Additionally, the sheets should have a balanced laminate structure to ensure stability and flatness.

The manufacturing process also plays a role in the selection criteria. Sheets should be cured under controlled pressure and temperature to achieve the desired mechanical strength. For roofing applications where aesthetics are a concern, the finish on one side of the sheet should be considered, ensuring it meets the visual requirements of the project.

Lastly, the potential for customization should be assessed. While some manufacturers may not offer custom fabrication for small quantities, it's important to know the range of sizes available to ensure they meet the project's needs without excessive waste or additional cutting. The method of cutting the fiber sheets is also a consideration, with techniques like water jet cutting or CNC routing being preferred over methods that may compromise the material's integrity.

Material Composition and Properties

Fiberglass, a type of fiber-reinforced plastic where glass fiber acts as the reinforcement, is notable for its lightweight, strength, and formability into various shapes. These characteristics stem from the glass fibers which can be flattened into sheets or woven into fabrics, tailored to specific applications. The versatility of fiberglass is due to the different types of glass that can be used in its production, affecting its properties and suitability for various uses.

The material properties of fiberglass make it an ideal choice for roofing applications. Its composition allows it to provide excellent thermal insulation and durability, which are critical factors for materials used in roofing. Furthermore, the inherent strength of fiberglass, coupled with its reduced brittleness compared to other materials, contributes to its longevity as a roofing solution.

Durability and Lifespan

FRP (Fiber Reinforced Polymer) roof sheets are recognized for their robustness and ability to withstand environmental factors like UV rays and weathering. The longevity of these sheets can be influenced by the quality of materials, installation methods, and environmental conditions. Typically, a well-maintained FRP roof sheet has the potential to last for over two decades. Maintenance practices, such as regular cleaning and prompt repairs, play a crucial role in extending the life of these roofing solutions. It's essential to conduct frequent inspections to identify and rectify any damage or wear early on.

The material quality is a pivotal factor in the lifespan of FRP roof sheets. Opting for sheets from manufacturers with a reputation for reliability can contribute to a longer-lasting roof. Environmental conditions are also a significant consideration; for instance, areas with high UV exposure, extreme temperatures, or considerable precipitation can accelerate the degradation of roofing materials. Selecting FRP sheets that are tailored to withstand specific environmental challenges is crucial for maximizing their lifespan and ensuring the durability of the roofing system.

Application Techniques for Fiber Sheets

For those considering fiber sheets for roofing applications, understanding the installation process is crucial. These sheets are known for their ease of installation with common tools and can be drilled, sawed, punched, or nailed without damage. When installing, it's important to start at the leeward side of the roof to protect against wind and weather. Overlapping is essential for preventing leaks; a minimum of one corrugation overlap at sides and an 8-inch end-lap for low-pitched roofs is recommended. Fastening should be done through the crowns at every second corrugation, using fasteners with Neoprene washers to ensure a tight seal. During installation, pre-drill holes slightly larger than the fastener diameter to accommodate expansion and contraction, which is particularly important for fiberglass-reinforced panels. To maintain the integrity of the sheets, avoid walking on them and ensure that screws are tightened just enough to prevent washer rotation, followed by an additional turn. By adhering to these application techniques, fiber sheets can provide a durable and effective roofing solution.

Installation Best Practices

For optimal installation of corrugated fiber sheets, it's crucial to follow best practices that ensure stability and longevity. Begin by pre-drilling holes in the panels, which should be larger than the fastener diameter—1/16" for fiberglass and 1/8" for PVC and Polycarbonate—to accommodate expansion and contraction. Install panels starting from the leeward side, progressing to the windward end, to protect against wind and weather. Overlap corrugations by at least one ridge and use an 8" end-lap for low-pitched roofs, reducing to 6" for steeper slopes. Secure the panels by fastening through the crowns at every second corrugation, with fasteners spaced 6" to 8" apart at the ends and 12" to 16" on intermediate supports. Use fasteners with Neoprene washers to prevent leaks, tightening just enough to prevent washer rotation plus an additional turn. To maintain the integrity of the seal, avoid over-tightening, which can cause deflection and damage to the panels. Lastly, ensure that all tools and fasteners are compatible with the material of the fiber sheets to prevent corrosion or damage.

Maintenance and Care for Longevity

Maintaining a fibre cement roof is crucial for ensuring its longevity and performance. Regular cleaning is essential; remove debris, leaves, and other materials that can accumulate and cause blockages in gutters or seams. Address any damage such as cracks or punctures promptly with appropriate sealants to prevent water ingress. It's also important to inspect the roof regularly for signs of wear, such as loose shingles or missing nails, especially around flashing areas, to avoid moisture buildup and corrosion.

Trees and shrubs near the roof should be kept trimmed to prevent branches from scratching or chipping the roofing material. If heavy items need to be stored on the roof, distribute the weight evenly to avoid damage. Walking on the roof should be avoided as fibre cement sheets can be brittle; if necessary, use a board to distribute your weight. Replace any cracked or broken sheets immediately to prevent water damage to the underlying structures.

For the screws and fixtures, use stainless steel to prevent rust and ensure they are tightened appropriately, but not overly so, to avoid damaging the panels. Regular checks for rust in gutters and downpipes can also indicate potential issues with water leakage. By following these maintenance tips, the durability of fibre cement roofing can be greatly enhanced, making it a reliable choice for protecting a property against various environmental conditions.

Advantages of Using Fiber Sheets from Alibaba.com

Fiber roofing sheets offer a range of benefits that make them a suitable choice for various roofing needs. These sheets are known for their resistance to diverse weather conditions, providing durability against elements like water, gas, and other potential leakage sources. The material's inherent strength contributes to its longevity, ensuring that it can withstand the test of time and the environment.

The versatility of fiber roofing is evident in its wide range of applications. From providing protection to enhancing the aesthetic appeal of a building, fiber sheets serve multiple purposes. They are also recognized for their insulating properties, which can contribute to energy savings. Additionally, the lightweight nature of fiber roofing sheets simplifies the handling process, making them a practical option for roofing projects.

Alibaba.com offers a diverse selection of fiber roofing sheets, including options that cater to specific functional and decorative preferences. The availability of various types and models allows buyers to select sheets that align with their project requirements and aesthetic desires. This selection underscores the adaptability of fiber sheets to different roofing scenarios, from residential to commercial applications.

Case Studies: Successful Roof Projects with Alibaba Fiber Sheets

Conclusion

In conclusion, fiber sheets represent a versatile and durable roofing solution, suitable for a wide array of applications. From the adaptability of fiber cement sheets in maintaining stable interior conditions to the aesthetic and functional diversity found on Alibaba.com, these materials offer significant advantages. The longevity and ease of maintenance of FRP sheets, coupled with their resistance to environmental factors, make them a wise investment for long-term roofing. Installation and care best practices ensure that these roofs can withstand the rigors of time and nature. By considering factors such as material composition, durability, and application techniques, property owners can leverage the benefits of fiber sheets to achieve a balance of practicality and aesthetic appeal. Alibaba.com's extensive range of fiber roofing sheets provides a plethora of options to meet the specific demands of any roofing project, ensuring that every structure is well-protected and visually pleasing.