Popular in your industry

Top categories

About flexible corner molding

When it comes to interior and exterior design, flexible corner molding is an essential component for creating seamless and aesthetically pleasing transitions between wall intersections and edges. This product is designed to fit smoothly around curved surfaces, providing a clean and finished look in a variety of settings.

Types and Materials of Flexible Corner Molding

The assortment of flexible corner trim types is vast, catering to a multitude of design requirements. Beyond the standard flexible rubber corner molding, there is flexible outside corner trim designed for exterior applications, which often features enhanced UV resistance to prevent degradation from sunlight. Flexible inside corner trim is tailored for interior use, where aesthetic versatility is crucial. For those seeking a more decorative touch, options like flexible l shaped plastic trim come in various colors and patterns, including faux wood grains that mimic the look of real wood without the associated maintenance. Each type is crafted to address specific corner molding needs, whether it's for durability in high-traffic areas or for a specific visual appeal in customer-facing environments.

Structural Features and Advantages of Flexible Molding

The structural design of flexible corner molding is ingeniously simple yet highly effective. The base of the molding is designed to adhere securely to the wall, providing a stable foundation. The spine, which is the flexible core, allows the molding to be manipulated to fit various curves and corners without losing its original shape. The face of the molding, which is the visible part, is crafted to present a smooth and finished appearance. This structure is particularly beneficial in products like flextrim flexible corner molding, which can be easily adjusted on-site to fit non-standard angles, a common challenge in custom and high-end construction projects.

Materials and Their Properties

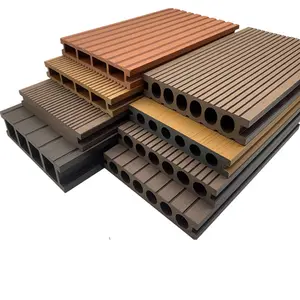

The selection of materials for flexible corner trim is critical to its performance and longevity. Rubber, known for its elasticity and resilience, is a popular choice for areas requiring impact resistance. WPC combines the aesthetics of wood with the moisture resistance of plastic, making it ideal for environments with fluctuating humidity. Metals like aluminum and steel are chosen for their strength and their ability to be powder-coated for extra durability and color retention. Each material is chosen not only for its physical properties but also for its environmental impact, with many manufacturers opting for recyclable or sustainable materials to appeal to eco-conscious consumers.

Business Usages and Applications

The use of flexible corner molding extends across various business sectors. In the hospitality industry, it contributes to the luxurious ambiance of hotel interiors. In commercial real estate, such as office buildings and apartments, it adds to the aesthetic value and can be a selling point for potential tenants. Retail spaces benefit from the polished look it provides, which can enhance the overall shopping experience and potentially drive sales. The practicality of these moldings in protecting wall edges from damage due to foot traffic or equipment movement translates to long-term cost savings for business owners.

Functions of Flexible Corner Molding

The primary function of flexible corner molding is to provide a protective and decorative interface between different wall surfaces. It is engineered to conceal gaps, cover imperfections, and prevent the accumulation of dust and debris in corner joints. Additionally, it can serve specialized functions such as cable concealment in office settings or providing a smooth transition between different wall materials or colors.

Features of Flexible Corner Molding

Flexible corner molding is characterized by its adaptability and ease of installation. Features such as self-adhesion, as seen in products like instatrim corners, make it possible to install without nails or screws, preserving the integrity of the wall surfaces. Some moldings are designed with a degree of transparency, allowing the underlying wall color to show through, which can be a subtle yet impactful design feature. The non-porous surface of many moldings also means they are resistant to staining and easy to clean, an essential feature in environments where hygiene is a priority.

Benefits of Flexible Corner Molding

The benefits of flexible corner molding are extensive. It not only improves the visual appeal of a space but also serves practical purposes such as edge protection and ease of maintenance. The flexibility of the material allows for quick adaptation to non-linear designs, which can be particularly advantageous in custom or avant-garde architectural projects. For property owners, the installation of such moldings can lead to an increase in property value due to the enhanced interior aesthetics.

How does flexible corner molding enhance building decoration?

Flexible corner molding enhances building decoration by bridging the gap between functionality and style. Its ability to conform to various angles and curves allows designers to create fluid transitions in spaces that might otherwise be interrupted by harsh lines or abrupt edges. The availability of different colors and finishes enables the molding to either stand out as a feature element or blend seamlessly with the existing decor, depending on the desired outcome.

What are the considerations for choosing the right flexible corner molding?

Choosing the right flexible corner molding involves assessing the specific needs of the project. Considerations include the degree of flexibility required, the compatibility of the material with the existing decor, and the environmental conditions of the installation area. For example, in areas with high moisture, a non-absorbent material like PVC would be preferable. The ease of installation is also a key factor, with options like peel-and-stick moldings being ideal for quick updates or renovations.

Are there sustainable options for flexible corner molding?

Sustainability is an increasingly important consideration in building materials. Flexible corner molding made from WPC is an excellent example of a sustainable option, as it utilizes recycled materials and is itself recyclable. Additionally, the longevity of these moldings means they need to be replaced less frequently, reducing waste over time.

How to ensure the longevity of flexible corner molding?

Ensuring the longevity of flexible corner molding involves proper installation and regular maintenance. The surface to which the molding is applied should be clean, dry, and free of debris to ensure optimal adhesion. Once installed, regular cleaning with mild detergents can prevent the buildup of dirt and grime, and immediate attention to any damaged areas will prevent further wear. Following these guidelines will help maintain the aesthetic and functional qualities of the molding for years to come.