Understanding Flexo Printing Ink

Flexographic printing, a method favored for its versatility and speed, relies heavily on the type of ink used. Flexo printing ink is a critical component in the printing process, influencing the final appearance, color fidelity, and texture of printed materials. This introduction delves into the various aspects of flexo inks, their applications, and how they cater to different printing needs.

Types of Flexo Printing Inks

The market offers a diverse range of flexo printing ink types to suit various printing substrates and purposes. Commonly, these inks are categorized based on the printing equipment they are designed for. Inks for laser printers, known for their durability, are distinct from those used in inkjet printers, which are optimal for lower volume printing tasks. Inkjet inks come in pigmented and dyed varieties, each with its own set of characteristics suitable for different print qualities and paper types.

Applications and Features

Flexographic inks are not limited to paper printing. They are also used for printing on plastics, metals, and other materials, making them ideal for labels, packaging, and marketing materials. The versatility of these inks allows for their use in various industries, from commercial to specialty printing. Features such as quick-drying times, resistance to fading, and the ability to adhere to different substrates make flexo inks a preferred choice for many professional printing tasks.

Materials and Advantages

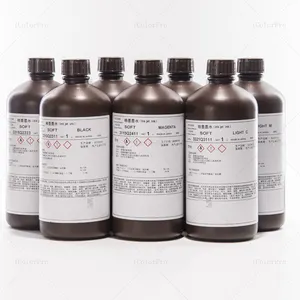

The composition of flexo printing inks is tailored to their specific application, with materials ranging from solvent-based to water-based formulations. Some inks incorporate UV-reactive components that cure instantly under UV light, offering durability and resistance to smudging. The advantages of using the appropriate flexo ink include enhanced print longevity, vibrant color reproduction, and the ability to print on a wide array of materials.

Selecting the Right Ink

Choosing the correct flexo ink requires consideration of the printing equipment, the desired output, and the printing medium. It is essential to match the ink type to the printer's specifications and the material to be printed on to achieve the desired results. While the selection process may seem daunting, it ensures that the prints produced meet the intended standards and application requirements.

Purchasing Flexo Printing Inks

When looking to procure flexo printing ink, Alibaba.com serves as a comprehensive marketplace that caters to a wide range of printing needs. Buyers can explore a variety of options, each designed to meet specific printing objectives. Whether the need is for a single cartridge or bulk purchases, the platform connects buyers with a plethora of suppliers, facilitating informed purchasing decisions without the constraints of minimum order quantities or limited selection.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4