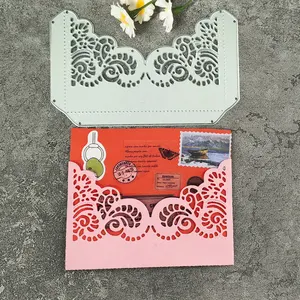

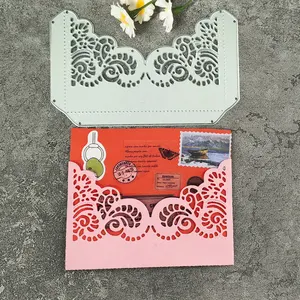

INS Lovely Flower Metal Carbon Steel Die Cut Embossing Stencil Cutting Dies For Invitation Card Making Craft Metal Die

AAGU Metal Cutting Dies Mould Scrapbooking Cutting Die Invitation Card Invitation Card Envelope Background Flower Craft Dies

The term flower die cut encompasses a variety of intricate cutting tools used to create detailed floral designs in various crafting projects. These dies are typically used with a die-cutting machine, allowing crafters and businesses to produce precise and uniform flower shapes for a multitude of applications, including card making, scrapbooking, and home decor. The precision of these tools ensures that each flower die cut shape is cleanly cut and ready for use in a professional or hobbyist capacity.

The flower die cut market offers an array of products, each with unique characteristics to cater to different crafting needs. The hydrangea die is known for its intricate, multi-petal design, perfect for creating lush floral clusters. On the other hand, carnation crafts dies are sought after for their classic, ruffled edges that mimic the real flower's texture. For tropical themes, the hibiscus die stands out with its bold, large petals. The sizzix flower die is a versatile option, compatible with various die-cutting machines and suitable for a wide range of materials. For those creating greeting cards or invitations, flower dies for card making are specifically designed to produce clean-cut, delicate flower shapes that add an elegant touch to paper crafts. The rose die cut and poinsettia die cut are particularly popular during festive seasons, symbolizing love and celebration. For a more rustic appeal, crafters may opt for a sunflower die cut or sunflower cutting die, which are perfect for fall-themed projects. Each type of die cut offers a different aesthetic and can be mixed and matched to create diverse and vibrant craft works.

The physical components of flower metal cutting dies include the die itself, which is a metal piece crafted into the shape of a flower. This die is often composed of sharp edges for cutting and intricate inner details for embossing. The structure is designed to fit into a die-cutting machine, where it operates in tandem with a base plate and cutting pads. The machine applies pressure, pushing the die into the material to be cut, such as paper or fabric. The sharp edges slice through the material, while the embossed details press into the surface, creating raised patterns and textures. This process can be repeated with various components, such as different layers of petals and leaves, to build up a three-dimensional flower design. The operation of these components together allows for the creation of complex and detailed floral patterns that would be difficult and time-consuming to cut by hand.

Flower metal dies are predominantly made from high-grade steel or carbon steel, chosen for their strength and durability. These materials are capable of withstanding the high-pressure environment of a die-cutting machine and are resistant to wear, ensuring a long-lasting sharp edge for consistent cutting. The choice of metal also allows for intricate designs that can cut through a variety of crafting materials, from delicate papers to heavier cardstock. The properties of these metals, such as resistance to corrosion and the ability to retain sharpness, make them ideal for the repetitive nature of die cutting in a business setting. The benefits of using such durable materials include reduced replacement costs and consistent quality in mass production, which are essential factors for businesses relying on these tools for their products.

In the business realm, flower die cuts are utilized across various industries. In the event planning sector, they are used to create custom decorations and favors that add a personal touch to weddings, corporate events, and parties. In retail, these dies are instrumental in producing unique packaging and displays that attract customers. Educational institutions use them to provide hands-on learning experiences in art classes. The versatility of flower metal cutting dies allows businesses to add value to their offerings and stand out in the market. For instance, a stationery company can use die cut flowers card making tools to craft exquisite, high-end greeting cards that command a premium price. Similarly, a home decor business can use these dies to create intricate wall art or embellishments for furniture, providing customers with unique, handcrafted options.

Flower die cuts are designed to perform specific tasks within the crafting process. Their primary function is to cut material into floral shapes with precision and consistency. However, beyond cutting, these dies can also emboss and stencil, adding depth and detail to the designs. Some dies are engineered to create fold lines for three-dimensional construction, allowing crafters to build up layers and create lifelike floral arrangements. The capability to perform multiple functions with a single tool makes flower die cuts a versatile and valuable asset in any crafter's toolkit.

The unique selling points of flower die cuts lie in their design and compatibility. Many dies feature interlocking pieces that allow for the creation of multi-layered flowers, providing depth and realism to the finished product. Some flower metal dies are also designed to be compatible with a range of die-cutting machines, making them accessible to a wider audience. Additionally, certain dies come with alignment marks or guides, which aid in positioning and layering, simplifying the crafting process. These features set them apart from competitors, offering crafters the ability to create complex designs with ease and efficiency.

The use of flower die cuts brings numerous benefits to crafters and businesses alike. They provide a means to quickly produce large quantities of uniform shapes, which is essential for maintaining consistency in product lines. The precision of die cuts also reduces material waste, as each cut is optimized to fit the design. For businesses, this translates to cost savings and a more sustainable production process. Additionally, the professional finish that die cuts provide enhances the overall aesthetic of the final product, contributing to higher customer satisfaction and perceived value.

Selecting the right flower die cut involves considering the specific needs of your project or business. Assess the type of material you will be cutting most frequently, and ensure the die is suitable for that purpose. Look for dies that offer the level of detail required for your designs, and consider the size of the die in relation to the die-cutting machine you have. It's also wise to choose dies from reputable manufacturers to ensure quality and durability. For businesses, dies that offer quick and easy alignment can save time in mass production, making them a more efficient choice.

Proper maintenance of your flower die cuts is crucial for their longevity. After each use, it's important to clean the dies to remove any residual material. A soft brush or a blast of compressed air can dislodge tiny paper pieces or fibers. Storing the dies in a protective case or on a magnetic sheet can prevent damage to the cutting edges. Regular checks for signs of wear or dullness can help you determine when a die may need to be replaced before it affects the quality of your cuts.

To fully leverage the potential of flower die cuts, crafters should explore various materials and techniques. Combining die cuts with other crafting methods, such as stamping or coloring, can result in unique and intricate designs. Experimenting with layering different sizes and types of flower dies can create dimensional and realistic floral arrangements. Additionally, using the dies to create stencils opens up possibilities for mixed media projects. By pushing the boundaries of traditional die cutting, crafters can discover new ways to enhance their creations and offer innovative products to their customers.