Popular in your industry

Related Searches:

Top categories

About ftth drop cable machine

Introduction to FTTH Drop Cable Machinery

The realm of fiber optic communication has been revolutionized by the advent of FTTH (Fiber to the Home) technology, which brings high-speed internet connections right to the doorsteps of residential and commercial buildings. Central to this technology is the FTTH drop cable machine, a specialized device designed for the production of drop cables that are a critical component in the FTTH network.

Types and Components

FTTH drop cable machines come in various types, each tailored to specific production needs. Common to these machines are core components such as PLC (Programmable Logic Controller), motors, and bearings, which collectively ensure precision and efficiency in cable production. The choice between different machines typically depends on the desired function, whether it's extruding the cable sheath or wrapping the cable with protective layers.

Applications and Features

The application of FTTH drop cable production equipment extends across the telecommunications industry, particularly in the manufacturing of lightweight and durable cables used for last-mile connectivity. These machines are equipped with features that allow for the handling of delicate fiber optics, ensuring that the integrity of the fibers is maintained throughout the production process.

Materials and Advantages

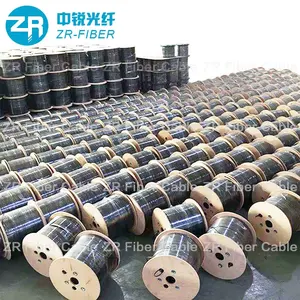

Materials used in the construction of FTTH drop cables include high-grade plastics and glass fibers, which are processed by the FTTH cable machinery to produce cables that are not only flexible but also resistant to environmental factors. The advantage of using such specialized machinery lies in the precision and scalability of production, allowing for consistent quality and the meeting of high demand in the burgeoning fiber optic market.

Operational Excellence

Operational excellence in FTTH drop cable machines is characterized by their automation capabilities and user-friendly interfaces. These machines are designed for continuous operation, minimizing downtime and maximizing output. The integration of advanced technologies in fiber optic cable machinery ensures that the production process is both cost-effective and meets the stringent standards of the telecommunications industry.

Choosing the Right Machine

Selecting the appropriate FTTH drop cable manufacturing machine is crucial for businesses looking to establish or expand their production capabilities. Factors to consider include the machine's compatibility with different types of fiber optics, its production capacity, and the level of automation it provides. While Alibaba.com does not endorse any particular brand or make guarantees, the platform offers a comprehensive listing of suppliers, each providing detailed information to help buyers make informed decisions.