Hat Moulding Machine Overview

The hat moulding machine is a specialized piece of equipment designed for the production of headwear. These machines play a crucial role in the cap manufacturing industry, enabling the mass production of hats in various shapes and sizes. With a focus on efficiency and precision, hat moulding machines cater to a range of production requirements, from small boutique operations to large-scale manufacturing plants.

Types and Applications

There are several types of hat moulding machines available, each suited to different manufacturing needs. Some are tailored for sports caps, while others are designed for fashion hats or industrial safety helmets. The applications of these machines are diverse, servicing sectors such as retail, garment shops, and promotional event companies. The adaptability of these machines allows for customization in hat design, ensuring a broad spectrum of end products.

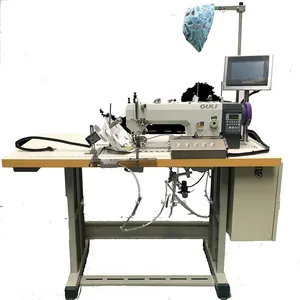

Operational Features

A hat moulding machine typically comes equipped with various operational features that enhance production capabilities. These include programmable logic controllers (PLCs), efficient motors, and sometimes engines, depending on the machine's complexity. The integration of advanced technologies facilitates seamless operation and the ability to produce hats with consistent quality.

Material Compatibility

The construction of hats involves a variety of materials, and modern hat moulding machines are built to accommodate this diversity. They can handle materials ranging from textiles and plastics to more sustainable options, allowing manufacturers to meet different market demands and adhere to material-specific production standards.

Advantages of Modern Machines

Today's hat moulding machines offer numerous advantages. They are designed for energy efficiency, reducing operational costs for manufacturers. The precision of these machines minimizes material waste, and their speed ensures that production can keep pace with market demand. Additionally, the automation capabilities of these machines reduce the need for manual labor, leading to a more streamlined production process.

Choosing the Right Machine

Selecting the appropriate hat moulding machine is vital for any business in the headwear industry. Factors to consider include the machine's capacity, compatibility with different materials, and the specific types of hats intended for production. While Alibaba.com does not manufacture these machines, the platform provides a connection between buyers and a wide array of suppliers, each offering machines with different features and capabilities to meet various production needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4