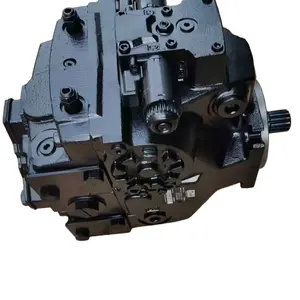

Understanding Hydraulic Axial Pistons

Hydraulic axial pistons are integral components in modern machinery, playing a pivotal role in hydraulic systems. These pistons are designed to convert fluid power into mechanical power and vice versa, functioning as the heart of hydraulic equipment. Their application spans across various industries, from construction to manufacturing, ensuring smooth operation and control.

Types and Applications

The versatility of hydraulic axial pistons is evident in their various types, such as the axial piston pump and axial piston motor. These components are essential in systems requiring precise control of fluid volume and pressure. For instance, an axial piston variable pump adapts to different flow requirements, making it suitable for complex machinery. In contrast, the axial piston hydraulic motor is often employed in mobile equipment and industrial vehicles due to its robustness and reliability.

Features and Materials

Hydraulic axial pistons are characterized by their durability and efficiency. Materials such as high-grade steel and advanced composites are commonly used to withstand the demanding conditions of hydraulic operations. The design of an axial piston hydraulic pump focuses on minimizing friction and wear, which is crucial for maintaining performance over time. Similarly, the variable displacement axial piston pump features adjustable settings to cater to specific system demands, enhancing its functionality.

Advantages of Hydraulic Axial Pistons

The advantages of using hydraulic axial pistons include their ability to deliver consistent power output and their adaptability to various workloads. The rexroth a10vso model, for example, is known for its seamless integration into different hydraulic systems, offering flexibility and control. Moreover, the rexroth a4vso series provides a reliable solution for high-pressure applications, ensuring that machinery operates at peak efficiency.

Selection Criteria

Choosing the right hydraulic axial piston requires a thorough understanding of the machinery's specifications. Factors such as displacement, pressure rating, and fluid compatibility must be considered. For specialized applications, a rexroth variable displacement pump might be the ideal choice due to its ability to provide variable flow rates. On the other hand, the a11vo series offers a solution for systems that demand high performance and low maintenance.

Integration in Hydraulic Systems

Integrating a hydraulic axial piston into a system requires careful consideration of the component's specifications and the system's requirements. Whether it's upgrading a axial plunger pump or selecting a rexroth axial piston pump for a new installation, the compatibility and efficiency of the component are paramount. By ensuring that the chosen piston matches the system's needs, one can achieve optimal performance and longevity of the machinery.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4