Understanding Internal Square Threads

Internal square threads are a specialized type of threading found in various applications where high strength and precision are required. These threads are characterized by their square-shaped cross-section, which differs from the more common triangular or rounded thread profiles. This unique shape allows for greater load-bearing capacity and durability, making internal square threads a preferred choice in heavy-duty applications.

Types and Applications

There is a diverse range of internal square thread types, each tailored for specific purposes. These threads are integral components in machinery and equipment, serving as critical connectors and adjustment mechanisms. Their applications span across industries, from automotive to aerospace, where precision and strength are paramount. The adaptability of these threads to various materials also broadens their usability, from metalworking to plastic-based manufacturing.

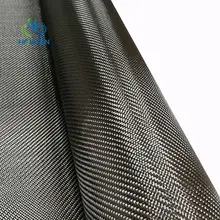

Features and Materials

The defining feature of an internal square thread is its geometric profile, which provides a high level of force transmission and resistance to wear. Manufacturers often use robust materials such as alloy steel and carbon steel to craft these threads, ensuring longevity and consistent performance under stress. The choice of material often depends on the application's specific requirements, such as corrosion resistance or tensile strength.

Advantages of Internal Square Threads

Internal square threads offer several advantages over other thread forms. Their design allows for easy engagement and disengagement, which is particularly beneficial in applications requiring frequent assembly and disassembly. The square profile also minimizes the risk of cross-threading, ensuring a secure fit every time. Additionally, the strength of internal square threads makes them suitable for heavy loads and high torque applications.

Selection Criteria

When selecting an internal square thread for a particular application, it is crucial to consider factors such as thread size, pitch, and material compatibility. It is also essential to evaluate the type of load and environmental conditions the thread will be subjected to. This careful consideration ensures that the chosen thread will perform optimally within its intended application.

Complementary Keywords

Internal square thread products are a niche yet essential category in the realm of threaded connectors. When sourcing these components, it is important to consider the thread cutting capabilities and the thread tapping tools required for installation. Suppliers may offer a range of services, including ODM (Original Design Manufacturing) and OBM (Original Brand Manufacturing), to cater to specific industry needs. Furthermore, the thread tools necessary for working with internal square threads are specialized, ensuring precision and quality in the final application.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4