Iseki Alternator Overview

An iseki alternator is an essential component in the realm of power generation, particularly for diesel engines. This device is pivotal in converting mechanical energy into electrical energy, ensuring that your machinery operates seamlessly even during power disruptions. The alternator iseki is commonly employed in various industrial applications, where consistent power supply is critical.

Types and Applications

The applications of an iseki alternator are diverse, ranging from agricultural machinery to industrial equipment. Depending on the required power output and application, these alternators come in different ratings such as Emergency Standby, Limited Time Power, Continuous, and Prime Rated Power. Each type is tailored to specific operational demands, ensuring that equipment functions effectively without interruption.

Features and Efficiency

An iseki alternator is designed for efficiency and durability. The absence of spark plugs and carburetors in these generators means fewer parts that require maintenance, leading to a more straightforward and cost-effective upkeep. Additionally, the robust design contributes to a longer running time, which is a significant advantage for prolonged industrial use.

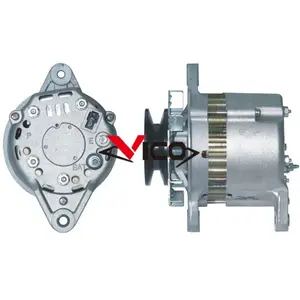

Materials and Construction

The construction of an iseki alternator involves high-grade materials that can withstand the rigors of heavy-duty use. The alternators are built to provide a reliable power source, with a focus on longevity and resistance to wear and tear. This ensures that they can maintain performance even under challenging conditions.

Advantages of Iseki Alternators

The primary advantage of using an alternator iseki is its ability to generate more power with a smaller engine, thanks to diesel's higher energy value. This efficiency does not compromise the output, making it a preferred choice for those seeking a reliable power generation solution. Furthermore, the design of these alternators allows for lower fuel consumption, which is not only cost-effective but also beneficial from an operational standpoint.

Understanding the Power Generation Process

The power generation process of an iseki alternator begins with the diesel engine converting chemical energy into mechanical energy. This mechanical energy is then transformed into electrical power by the alternator, which operates through the interaction of a wire and a magnetic field. This process is crucial for continuous industrial operations, especially in the event of power outages.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4