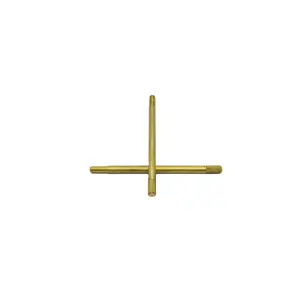

Exploring the Versatility of Knurled Shafts

Knurled shafts are integral components in various mechanical applications, known for their textured surface that enhances grip and torque transmission. These shafts are crafted to meet the needs of diverse equipment, ensuring functionality and precision across industries.

Types and Materials of Knurled Shafts

Knurled shafts are available in a spectrum of materials, each offering distinct characteristics. The steel knurled shaft is celebrated for its robustness and longevity, making it a preferred choice for applications demanding high control and precision. In contrast, the graphite knurled shaft is significantly lighter, providing an alternative for users seeking ease of handling without compromising on strength. For those looking for a blend of both, the multi-material knurled shaft combines steel and graphite, delivering a balanced experience of durability and lightweight design.

Applications and Flexibility

The application of a knurled shaft is vast, with its adaptability being a key attribute. The flex of a shaft is crucial as it influences the trajectory and velocity of a golf ball, for instance. Golfers with rapid swing speeds might opt for a knurled shaft with reduced flex, while those with gentler swings may benefit from increased flex. For novices, a shaft with more flexibility is often suggested to accommodate the learning curve.

Technical Specifications

Understanding the technical nuances of knurled shafts is essential for selecting the right fit. Torque, measured in degrees, is a pivotal specification that varies among shafts. Graphite shafts typically exhibit a torque between seven to eight degrees, allowing for a considerable degree of twist during a swing. Conversely, steel shafts generally offer a lower torque range of two to four degrees, resulting in a stiffer feel during use.

Customization and Selection

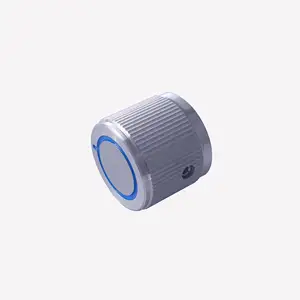

Customization is at the forefront when it comes to knurled shafts, with options like the 6mm knurled shaft catering to specific diameter requirements. Additionally, the coarse knurled pot shaft is another variant that provides a unique texture for enhanced manual adjustment, suitable for a range of industrial applications.

Conclusion

Selecting the appropriate knurled shaft is a nuanced process that hinges on understanding the interplay between material, flex, and torque. With a variety of options available, from the 6mm knurled shaft to the coarse knurled pot shaft, users can find the right component that aligns with their specific mechanical requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4