Metal Parts Manufacturing High Tonnage Power Press ALE-500 Double Crank Precision Steel Frame Press Machine

Aluminium Punching Machine Machine Tool Equipment Mechanical Small Punching Machine For Aluminium Profile Press Machine Metal Press

China Press Brake Price Small Hydraulic 40T1600 Press Brake 1mm Stainless Metal Steel Plate Folding Bending Machine

Da53t 4+1 Axis Press Brake Molds Hydraulic Press Brake Bending Machine Servo Press Brake

Hydraulic Press Brake Bending Machine 125T/3200 Da53T 4+1 Axis Hydraulic Press Brake Sheet Metal Folding Bending Machine

Hydraulic Press Brake Bending Machine Hydraulic Sheet Bending Machine WE67K 100T3200MM Iron Sheet Press Brake Bending Machine

CNC Electric Hydraulic Servo Proportional Press Brake CNC Sheet Folding Folder Machine Manual Metal Bending Machine

Gweike bending machine CNC Pressbrake for sheet metal brake press tools manual sheet bending machine

wc67k 63t 2500 mm electrical press brake Manual sheet metal Cnc Metal Bending Machine Mini Press Brake Machine

Zyco Wc67k 125t 3200mm Aluminum Composite Panel Nc Press Bending Machine E21 Motor Sheet Metal Bending Machine Manual

Hot sales hydraulic press break machine electric sheet metal bending machine stainless manual steel bending machine

manual Metal sheet bender/manual sheet bending press brake machine PBB-1.5*12703S

DELEM DA53T Wc67k We67k 200T 3200mm Plate Metal Sheet Hydraulic CNC Press Brake Machine small 10mm Price Manual Bending Machine

Multifunctional small manual sheet metal cnc press brake machines 10t 50ton Small Segment Cnc Sheet Metal Servo Bending Machine

hydraulic manual sheet metal folding hand press brake machines for sales

Sheet Metal Bending Machine / Manual Folider Machine price PBB1020/3SH

WC67K 125T 3200 4+1 6+1 axis sheet metal press brake cnc Hydraulic manual bending machine

Rbqlty J23 Series 25T 40T 63T Mechanical Punch Press Machine Manual Punch machine for Metal Hole Punching

sheet metal manual edge bending machine

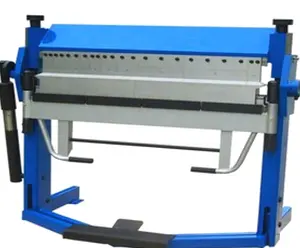

JG67 Series Manual Pan Brake Hand type manual plate bending machine Manual Sheet Metal the iron hand folding machine

Manual Sheet Metal bending Machine PBB1020/2A PBB1270/2A Folding Machine

CNC hydraulic press break machine 63T electric sheet metal bending machine WC67K stainless manual steel bending machine

Manual Sheet Metal Bending Machine iron Sheet Metal hand folding machine

Gweike Cnc Manual Sheet Bending Machine 200T 300T 500T Hydraulic Press Brake Metal Bending Machine

125T 4M Servo Motor Used Hydraulic Press Brake Machine Price Manual Sheet Metal Bending Machine Bending Pipe Machine

In stock manual iron bender/manual folding machine / manual sheet metal folder

Electromagnetic Manual Sheet Metal Bending Machine with CE Magnabend 2000E

china high quality Manual Sheet Metal Folding Machine bending machine factory For Duct Forming Machine

PLSON manual hand sheet metal folding machines manual

ACCURL Press brake 250 ton/hydraulic press brake machine WC67Y-250*5000/metal sheet manual folding machine

Hydraulic Manual Press Brake Stainless Steel Sheet Metal Plate Bending Machine

REBEST Hydraulic Metal Sheet Bending Machine Metal Plate Press Break Manual CNC Press Break Machine

100Ton 160Ton 200T Manual Sheet Metal Hydraulic NC Brake Press Brake Bending Machine

Manual Sheet Metal Bender Price WC67Y 125T press brake 1000mm Steel Bending Machine

Used Manual Press Brake Sheet Metal Bending Machine

manual sheet metal Bending machine / pipe Bending machine price / profile Bending machine

JULY factory manual pneumatic metal embossing press machine

1250x2.0mm Manual Electric magnetic Sheet Metal bending machine

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4