Introduction to Metal Flattening Machines

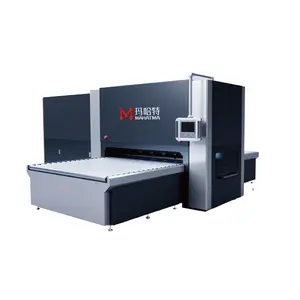

Metal flattening machines are essential in transforming metal into flat sheets through a process of rolling and pressing. These machines cater to various sectors, including automotive, aerospace, and construction, where precision and consistency are paramount. The category encompasses a range of equipment, from sheet metal flattening machines to steel plate flattening machines, each designed to address specific metalworking needs.

Types and Applications

The diversity of metal flattening machines includes plate flattening machines and sheet flattening machines, each serving distinct functions. Plate flattening machines are typically employed in heavy-duty applications, handling thicker metal plates. In contrast, sheet metal flattening machines are more suited for thinner, more delicate metal sheets. These machines are indispensable in industries where sheet metal is a primary material, ensuring the metal's flatness before it is cut or shaped further.

Features and Materials

A metal flattening machine is designed to withstand the rigors of industrial environments. Constructed from durable materials, these machines can manage the stress of flattening various metals, including steel, aluminum, and copper. The inclusion of sheet metal flattening rollers in some models enhances the precision with which metals are flattened, ensuring an even surface without warping or distortion.

Advantages of Modern Flattening Machines

Modern steel flattening machines bring efficiency and reliability to the manufacturing process. Their robust construction allows for continuous operation, a critical factor in maintaining productivity. The precision engineering of these machines ensures consistent output, which is crucial for manufacturers who rely on uniformity in their products.

Choosing the Right Machine

Selecting the appropriate metal flattening machine requires an understanding of the specific manufacturing needs. Factors such as material type, thickness, and the scale of operation play a significant role in determining the most suitable machine. Prospective buyers should consider the machine's compatibility with their existing manufacturing processes and the material it will be handling.

Conclusion

In conclusion, the range of metal flattening machines available caters to a broad spectrum of industrial requirements. From steel plate flattening machines to those designed for lighter metals, each machine plays a pivotal role in ensuring the quality and consistency of metal products. While exploring options, it is essential to assess the machine's specifications and its alignment with the operational demands of the business.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4