Introduction to Micro Winding Machines

Micro winding machines are specialized devices designed to produce precise and miniature coils used in various electronic components. These machines cater to the intricate process of winding wire around a core to create transformers, inductors, and other electromagnetic products. With the advancement of technology, these machines have become essential in producing high-precision windings necessary for the miniaturization of electronic devices.

Types and Applications

There are several types of micro winding machines, each serving a specific function. Some are tailored for heavy-duty industrial use, while others are more suited for delicate, precision-based tasks. The applications of these machines are vast, ranging from the automotive industry, where they are used in the manufacturing of sensors and actuaries, to the medical field for creating coils used in diagnostic equipment. Additionally, they play a crucial role in the consumer electronics sector, contributing to the manufacturing of components found in smartphones and other gadgets.

Features and Materials

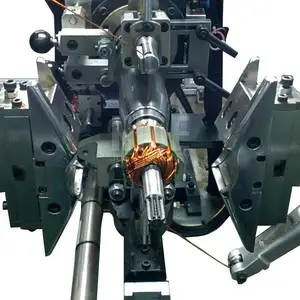

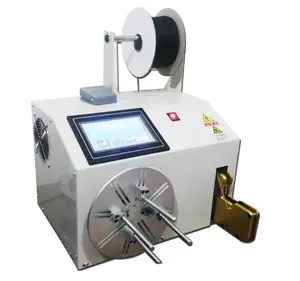

A micro coil winding machine typically features advanced programming capabilities, allowing for the automation of the winding process and ensuring high accuracy and repeatability. The materials used in the construction of these machines are chosen for their durability and ability to withstand the demands of continuous operation. Components are often made from hardened steel or other alloys, which provide the necessary strength and precision.

Advantages of Modern Winding Technology

The latest models of coil winding equipment offer significant advantages over manual winding methods. They ensure uniformity in coil production, which is critical for the performance of electronic devices. The precision offered by an automatic winding machine also minimizes material waste and improves the overall efficiency of the manufacturing process. Furthermore, the integration of computerized control systems allows for quick setup and changeovers, making them suitable for both high-volume production and small, custom batches.

Operational Efficiency and Precision

Operational efficiency is paramount in manufacturing, and a precision winding machine is designed to meet this need. With features that allow for single-person operation and options for fully automated systems, these machines streamline the production process. The precision of an automated winding machine ensures that each coil is wound to exact specifications, which is critical for the functionality of the final product.

Choosing the Right Machine for Your Needs

Selecting the appropriate micro winding machine requires a thorough understanding of your project's specific needs. Alibaba.com hosts a diverse range of machines, each with detailed descriptions and specifications to aid in your decision-making process. Whether you are involved in construction, farming, or manufacturing, the platform provides access to a wide selection of machines to suit various project scales and complexities.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4