A mineral powder granulating machine is a vital piece of equipment for transforming fine mineral powders into granules, thereby enhancing their usability across various industries. Such machinery is pivotal for sectors dealing with powdered substances, improving their ease of handling, transportation, and usage, notably in the realms of fertilizer production, chemical processing, and pharmaceuticals. The granulation process is key to augmenting product flow, diminishing dust, and heightening the solubility of the products.

Types and Characteristics of Mineral Powder Granulating Machines

The mineral powder granulating machine category includes a variety of models, each designed with distinct features to meet specific industrial requirements. Disc granulators are prized for their production of uniform granules and are especially adept at handling fine powders. Double roller press granulators stand out for their high efficiency and are well-suited for large-scale, continuous production environments. Pan granulators are known for their adaptability, capable of processing a broad spectrum of materials, which makes them appropriate for a range of operational sizes. Each granulator is engineered to cater to particular industry needs, offering different granule sizes, processing speeds, and capacities to suit various applications.

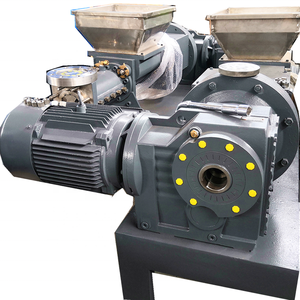

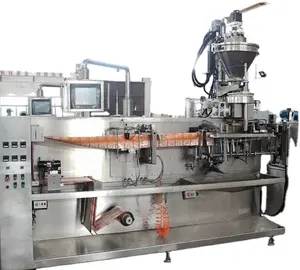

Structure and Operation of Granulating Machines

The mineral powder granulating machine features a sophisticated design that includes a hopper for material intake, a granulation chamber for processing, a motor and gearbox for power, and a PLC system for operational management. The pressure vessel is the site of granulation, while the pump facilitates material movement within the machine. Each component plays an integral role in the machine's function, collaborating to ensure granulation is both efficient and effective. The design and synergy of these parts enable the machine to operate seamlessly, consistently producing high-caliber granules.

Materials and Engineering Considerations

The construction of a mineral powder granulating machine involves materials selected for their robustness and suitability for the granulation process. Stainless steel is commonly employed for parts in contact with materials to avert contamination and withstand corrosion. The motor and bearings are constructed from materials capable of enduring the rigorous demands of granulation operations. These material choices reflect a calculated engineering strategy aimed at achieving an optimal balance between performance, durability, and maintenance needs.

Business Usages and Industrial Applications

Mineral powder granulating machines are instrumental in various sectors by transforming powders into granules, thus improving product management and quality. In the realm of fertilizers, these machines are indispensable for producing consistent granules that promote uniform field application. In pharmaceuticals, granulation is crucial for dosage uniformity. The construction sector benefits from granulated minerals used as additives in building materials, which enhance the characteristics of the end products. These machines contribute substantial business value by enhancing product uniformity, minimizing waste, and elevating the quality of industrial goods.

Functions and Tasks of Granulating Equipment

The mineral powder granulating machine is engineered to execute several pivotal functions in the granulation process. It amalgamates raw materials, shapes the powder into the desired granule sizes, and may also incorporate a drying phase to attain the ideal moisture level. The specific capabilities of the machine vary with the granulator model, but all aim to produce uniform and superior granules that adhere to exacting industry standards.

Features and Unique Selling Points

Key attributes that set apart a mineral powder granulating machine include its high output, competitive cost, and extended operational lifespan. Advanced models boast automatic operation, energy efficiency, multifunctionality, and precision. These characteristics offer operators a spectrum of operational options and differentiate the machines from competitors, providing distinctive selling points that address a wide array of granulation requirements.

Benefits and Positive Outcomes

Employing a mineral powder granulating machine yields a multitude of advantages. It tackles the issue of managing fine powders by converting them into more manageable granules, leading to enhanced handling, waste reduction, and superior quality control in product fabrication. The resulting granules exhibit improved flow characteristics and are less prone to segregation, ensuring product consistency and more streamlined industrial processes.

How to Choose the Right Granulating Machine?

Selecting the suitable mineral powder granulating machine requires evaluating the material properties, desired granule size, production volume, and the machine's essential components. The availability of after-sales service is also a crucial factor. Opting for a machine accompanied by a comprehensive machinery test report can offer assurances regarding the machine's dependability and operational prowess.

How to Maintain Your Granulating Machine?

Ensuring the longevity and optimal performance of a mineral powder granulating machine necessitates regular maintenance, including the servicing of motors, bearings, and pressure vessels. Access to after-sales services such as online assistance and video technical support is vital for prompt troubleshooting and maintenance, guaranteeing the machine's sustained peak efficiency.

How to Install a Mineral Powder Granulating Machine?

Installing a mineral powder granulating machine is a crucial procedure that demands professional expertise. It entails assembling the main structure, connecting the power source, and setting up the PLC. Engineers available for overseas machinery servicing can offer invaluable support during the installation, ensuring the machine is correctly configured and operational from the outset.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4