All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(10106 products available)

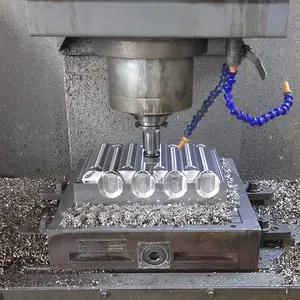

The mst makina is a set of tools and machinery for different technical jobs, both large and small. These parts come in many types to handle various cutting needs, from smooth cuts for metal to sharp cuts for heavy tasks. Here are some common kinds of mst makina.

Mst metal cutter is known for its precision and smooth finish. It uses sharp teeth on the blade to cut metal gently, leaving no rough edges. This makes it ideal for tasks where fine details are important, especially in car parts, aircraft, or equipment. Using this machine lowers the cost since it doesn't require much polishing or extra work after cutting.

This type of cutting tool uses a long, thin metal strip with teeth, called a blade, to cut things. It is good at cutting large pieces of metal, wood, or other materials. The 'band' blade allows it to make curved cuts and is often used in factories or workshops for bulk cutting tasks.

A circular cutting device has a round blade that cuts fast and straight. It is perfect for trimming or slicing flat materials like wood into smaller pieces quickly. Many construction workers and builders use it to make clean cuts in their work. However, care is needed when using it, as the blade cuts deeply and can be dangerous if misused.

This machine is used to cut small holes or notches out of metal sheets or bars. It works by punching out a piece of metal and leaves notches shaped like a U or V. These notches are helpful when bending parts into certain shapes. This machine is an important tool for workers making metal frames, brackets, or supports.

The angle cutting shear machine cuts materials at specific angles. It makes triangular cuts that help shape metal, wood, or plastic pieces into angled parts needed for projects. This shear is often used in construction or manufacturing where angled cuts are regularly required for building supports, joints, and other framework pieces.

The mst makina has many uses across different fields. It stands out because of its ability to perform many tasks fast and help workers produce precise cuts in large quantities. Here are some common uses.

Mst machines are useful for making BOM and MOC parts. They help create precise cuts needed to produce strong supports for large building projects. The ability to cut quickly and accurately allows workers to make many parts fast, important for complex jobs with large amounts required.

Heavy cutting machines are valuable in making modular racking systems. Their power enables them to slice through tough metals or large pieces quickly, allowing workers to manufacture many racks fast. The machine's precision ensures the cuts are accurate, helping the racks fit properly and supporting heavy loads without bending or breaking.

These machines make controlling cuts easy, which allows for the quick production of many piping support brackets. The machine is strong enough to cut thick metal, which is useful since piping brackets need to be strong parts that withstand heavy pipes. Accurate cuts ensure each bracket fits correctly, allowing the whole system to be built precisely.

In industrial furniture, Mst machines enable quick, precise cuts needed for large work tables, storage racks, or custom cabinets. Their strength lets them handle the biggest materials, making them crucial in factories where many durable, heavy pieces of furniture must be produced in a timely way without sacrificing quality.

Mst machines help speed up the equipment parts making process. Their ability to cut large sheets of metal or other materials quickly allows workers to manufacture important components like frames, panels, or mounts without delay. The machine's precision ensures each part meets specs so equipment works properly and reliably when put together.

Mst machines come with strong parts to handle tough tasks. The main motor produces 15 kilowatts of power to keep the machine running fast. It can cut materials up to 80 millimeters thick. The working table measures 1.4 by 1.2 meters, providing ample space to work on large items. The machine can operate at different speeds for precise control. Also, its hydraulic clamps hold materials tightly, allowing for steady and safe cuts.

Installing the Mst cutting machine requires some careful setup. First, find a flat, steady spot with room for the machine and space to work. Then, connect it to the correct power source by wiring it to the main electrical line. After that, secure the hydraulic pipes to the proper places, ensuring they tightly connect.

Start the main motor and adjust the feed speed and cutting angle to the desired settings. Then, place the material on the working table and use hydraulic clamps to secure it in place. Finally, press the control buttons to engage the shear blades and begin the cutting process. Use safety gear throughout the operation for protection.

To maintain the MST machine, clean it daily with a cloth to remove dust and debris. Apply lubrication oil weekly to keep the moving parts smooth. Inspect the blades and hydraulic system every month for any signs of wear. Replace worn blades and check hydraulic seals as needed. The main parts should be serviced annually by a trained technician to ensure all internal components function properly.

Quality is critical to keep the Mst makina running well for a long time. Regular checks of key parts like the blade and clamps must happen so the machine performs correctly. Lubrication of moving pieces also needs to happen so they do not wear out from friction. Owners should clean the machine too, as dirt affects the cuts. Only skilled workers should use it, as improper use causes damage.

Safety stands out when operating this machine. Workers must wear guards for their hands and protective glasses to keep dust and shards from hurting them. Loose clothes and untied hair could get caught in the machine, so these need control. Keeping one hand on the switch when cutting allows immediate halting if needed, decreasing the chance of injury.

Mst cutting tools require regular upkeep to run well. Owners should clean blades after each use to remove metal bits and material. Machines need oil on gears and joints every few days to prevent rust. They also should check wires, hydraulics, and other parts for wear monthly. Any damaged piece must get fixed right away. Finally, machines need professional inspection at least once a year - this ensures all parts work well to stay safe to use.

A1. The MST makina cuts metal, serving as a vital tool in factories and construction sites. It slices metal sheets, pipes, and rods quickly, making it great for large jobs. Many industries need sharp, accurate cuts for their projects, and this machine handles such important tasks.

A2. Factories, construction, ship repair, and machinery firms rely on it. It aids in part creation for tools, equipment, and structures. Moreover, it excels at quick, precise cutting for vast production needs, making it a valuable asset across industrial applications.

A3. The key parts include blades for cutting, hydraulic clamps to hold items still, a strong motor to power it, and a large work table for materials. All these elements enable the machine to cut with speed and accuracy, serving industrial demands effectively.

A4. Safety gear like glasses and gloves should get worn whenever using the machine. One hand should stay near the stop button. Clothes and hair must get secured to avoid catching in moving parts. Lastly, regular safety checks also help ensure safe operating procedures.

A5. Regularly scrub the machine, checking for wear on blades and parts. Lubricate moving areas based on instructions. Hydraulics and electrical components need inspection monthly. Repairs get done right away, and a yearly check by an expert ensures all parts function flawlessly.