Popular in your industry

Top categories

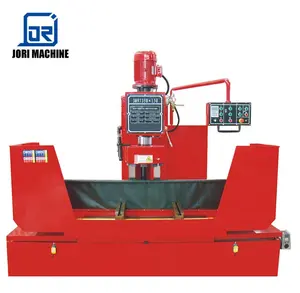

About parts of a grinding machine

Grinding machines are mechanical devices used for shaping or finishing metal parts through the process of abrasion. These devices use an abrasive wheel as the cutting tool that grinds metal workpieces. The primary keyword, parts of a grinding machine, refers to the components or elements that constitute a grinding machine and are essential for its proper operation. Grinder motors, as the power source, grinder gearboxes, as the transmission system, and various other elements, such as the wheel guards, coolant systems, and workpiece holders, are vital parts of a grinder. Each part plays a specific role in the grinding process, contributing to the machine's overall functionality and efficiency.

Grinder Motor

The grinder motor is the core power source of a grinding machine. It is responsible for providing the rotational force necessary to drive the abrasive wheel, enabling it to cut, grind, or finish the workpiece. Grinder motors are available in various types and configurations, including electric motors for conventional grinding machines and air-powered motors for pneumatic die grinders. The power rating of a grinder motor is a crucial consideration, as it determines the machine's grinding capacity. Higher power ratings result in more robust and faster grinding, making them suitable for heavy-duty applications. Conversely, lower power motors are better suited for light to medium grinding tasks. Moreover, the speed of the grinder motor is also significant. It is measured in revolutions per minute (RPM) and determines the rotational speed of the abrasive wheel. The speed of the grinder motor should be compatible with the type and size of the abrasive wheel to ensure safe and efficient grinding operations.

Grinder Gearbox

The grinder gearbox plays a critical role in transmitting power from the motor to the grinding wheel. It consists of a set of gears that work together to provide the necessary speed and torque for the grinding operation. Gearboxes are essential for adjusting the speed and direction of the grinding wheel to suit different applications. The material and design of the gears are crucial factors in determining the gearbox's durability and performance. Common materials for grinder gearboxes include hardened steel and alloy metals, chosen for their strength and wear resistance. The gearbox housing is another vital component, providing protection and support for the gear assembly. Gearboxes are lubricated to reduce friction and wear, ensuring smooth and efficient power transmission. Regular maintenance, such as checking and replenishing the lubricant, is essential to prolong the gearbox's lifespan and prevent malfunctions during operation.

Basic Parts of a Grinder

Grinding machines consist of several common components, each playing a specific role in the grinding process. The base is the foundation of the machine, providing stability and support during operation. The wheel guard encloses the abrasive wheel, protecting the operator from debris and preventing sparks from scattering. The work rest is an adjustable support that holds and stabilizes the workpiece during grinding. The coolant system is responsible for maintaining the grinding machine's temperature and lubricating the grinding wheel, reducing heat and friction. Additionally, the control panel houses the machine's controls and settings, allowing the operator to adjust parameters such as speed and feed rate. These basic parts are fundamental for a grinding machine's safe and efficient operation.

In conclusion, the parts of a grinding machine are diverse and interdependent, contributing to the machine's overall performance and functionality. The grinder motor, gearbox, wheel guards, coolant systems, and other components work in tandem to facilitate precise and efficient metal grinding operations.