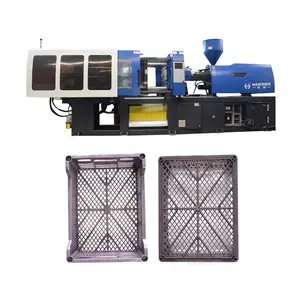

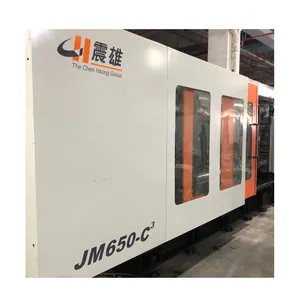

Introduction to Plastic Basket Making Machines

Plastic basket making machines are integral components in the manufacturing sector, designed for the production of various plastic containers. These machines utilize advanced technologies to mold plastic materials into baskets, catering to the needs of diverse industries. Their versatility in producing an array of sizes and shapes makes them a staple in plastic goods fabrication.

Types and Applications

The plastic basket making machine category encompasses a range of equipment, each tailored for specific production requirements. From compact units suitable for small-scale operations to industrial-grade machines for mass production, these machines serve multiple applications. They are pivotal in creating items such as thin-wall containers, caps, pails, and buckets, addressing the demands of the packaging industry and beyond.

Machine Features and Functions

A plastic injection moulding machine is engineered with a special screw design that enhances plasticizing capabilities, ensuring efficient shot weight and speed. The clamping force of these machines varies, providing the necessary resistance against external machining forces. This feature is crucial for maintaining precision during the production of complex basket designs.

Materials and Advantages

Typically, these machines handle a variety of plastic materials, including PVC, which is often used for pipe fittings and other robust products. The advantage of using a plastic extruder lies in its ability to recycle waste into usable materials, promoting sustainability in manufacturing processes. Additionally, the specialized design of these machines means that manufacturers can select a model with the exact clamping force required for their specific tasks.

Choosing the Right Machine

Selecting the appropriate plastic basket making machine involves considering the size of preforms and the desired production capacity. Machines available on Alibaba.com cater to a wide range of preferences, ensuring that businesses can find a model that aligns with their operational needs. It is essential to consider the plasticizing capacity and the clamping force to ensure the machine can handle the intended production volume and basket complexity.

Environmental Impact and Efficiency

Modern plastic basket making machines are not only efficient in production but also mindful of environmental impact. The ability to turn plastic waste into new products reduces the ecological footprint of plastic manufacturing. Efficiency in energy consumption and material use are key considerations for businesses aiming to optimize their production while being environmentally responsible.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4