Popular in your industry

Related Searches:

Top categories

About plastic beads making machine

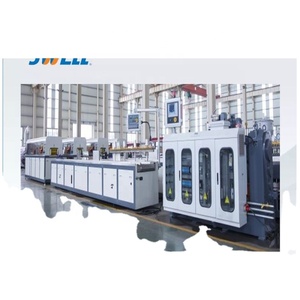

Introduction to Plastic Beads Making Machines

Plastic beads making machines are integral components in the field of plastic extrusion, a process vital for producing a diverse range of plastic products. These machines are designed to convert raw plastic materials into beads, which can be further utilized in various manufacturing processes. The efficiency of these machines makes them a cornerstone in industries that prioritize the reuse of plastics, contributing to more sustainable production practices.

Types of Plastic Beads Extruders

The market offers a variety of plastic extrusion equipment, each catering to specific production needs. Predominantly, these machines are classified into single screw and twin screw extruders. Single screw extruders are suitable for straightforward, less complex tasks, while twin screw plastic beads making machines are recognized for their enhanced efficiency and higher output, making them ideal for large-scale operations.

Applications and Versatility

The application of plastic beads making machines spans across numerous industries, from intricate medical components to robust construction materials. Their versatility is evident in their ability to produce a wide array of products, including pipes, profiles, and sheets, which are essential in sectors such as packaging, automotive, and consumer goods.

Features and Materials Compatibility

Modern plastic beads extruders are engineered to handle a vast range of materials, from HDPE to recycled plastics. Features such as precise temperature control and customizable molds allow for the production of beads with specific characteristics. The adaptability of these machines ensures that they can meet the diverse material requirements present in today's dynamic manufacturing landscape.

Advantages of Advanced Extrusion Technology

The latest advancements in plastic extrusion technology have led to significant improvements in the production process. Enhanced screw designs in plastic beads making equipment provide better mixing and melting, resulting in a more consistent product quality. Additionally, energy-efficient models contribute to reduced operational costs and support environmental sustainability efforts.

Choosing the Right Machine

Selecting the appropriate plastic beads making machine involves evaluating production capacity, material compatibility, and the specific end product requirements. While twin screw machines offer higher throughput, single screw machines may suffice for smaller-scale operations. It is crucial to assess the needs of your project to ensure the chosen machine aligns with your production goals.