Introduction to Plastic Fabrication Tools

Plastic fabrication tools encompass a broad range of equipment designed for the shaping, forming, and joining of plastic materials. These tools are integral to numerous industries, enabling the creation of components ranging from simple household items to complex industrial parts. The versatility of plastic fabrication equipment allows for a multitude of applications, ensuring that each design can be brought to fruition with precision and efficiency.

Types of Plastic Fabrication Tools

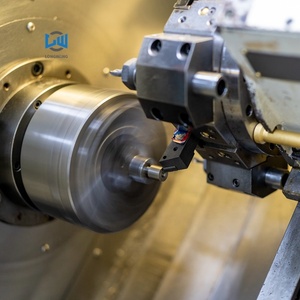

The category of plastic fabrication tools includes a variety of instruments and machines, each serving a specific function in the plastic production process. Among these, injection mold fabrication tools are prominent for their role in mass-producing plastic parts with intricate shapes. Other essential tools in this category include thermoforming machines, blow molding equipment, and extrusion devices, all tailored to different manufacturing requirements.

Applications and Features

Plastic injection mold fabrication tools are particularly beneficial for creating high-volume parts with consistent quality. These tools are engineered to handle various plastic types, from thermoplastics to thermosetting polymers. Features such as temperature control, pressure regulation, and cycle timing are critical in ensuring the molds produce parts that meet exact specifications.

Materials and Advantages

The materials used in the construction of plastic fabrication tools are chosen for their durability and resistance to wear. Common materials include metals such as steel and aluminum, which are often used in the creation of molds. The advantages of using these tools are manifold, including the ability to replicate parts with high precision, the reduction of waste through efficient design, and the potential for automation in the production process.

Choosing the Right Equipment

Selecting the appropriate plastic fabrication equipment is crucial for any project. Factors to consider include the type of plastic material, the complexity of the design, and the desired production volume. Suppliers on Alibaba.com offer a range of options, ensuring that buyers can find the tools that align with their specific manufacturing needs without compromising on the versatility or functionality of the equipment.

Streamlining Production with Standardization

To enhance efficiency, buyers may opt for standardization features within their plastic fabrication tools. This can include uniform lift bars, connection sizes, and clamp slots, which facilitate ease of use across various molds. Such standardization can lead to cost savings in production and maintenance, making it a strategic consideration for businesses looking to optimize their manufacturing processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4