Popular in your industry

Related Searches:

Top categories

About plastic injection moulding skeleton

Understanding Plastic Injection Moulding Skeletons

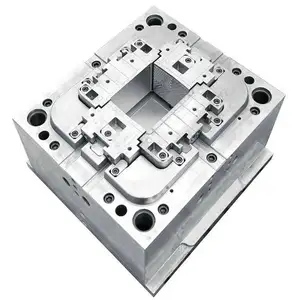

The plastic injection moulding skeleton is a foundational component in the realm of manufacturing, playing a pivotal role in shaping various plastic products. This framework is integral to the injection moulding process, where molten plastic is injected into a mould to create parts of diverse complexities and sizes. The skeleton, often a metal structure, ensures precision and durability during this process.

Types and Applications

Injection moulding skeletons come in various types, each suited to specific applications. From intricate components for electronic devices to larger parts for automotive manufacturing, the versatility of these skeletons is vast. They are also employed in creating consumer goods, medical equipment, and construction materials, showcasing their wide-ranging utility in different industries.

Material Considerations and Features

The choice of material for a plastic injection moulding skeleton is crucial, with options ranging from hardened steel to aluminum. Each material offers distinct features, such as thermal conductivity or corrosion resistance, impacting the moulding process's efficiency and the final product's quality. The design features of these skeletons, including cavities and cores, are tailored to meet the specific requirements of the intended product.

Advantages of Plastic Injection Moulding Skeletons

Utilizing a plastic injection moulding skeleton offers several advantages, such as enhanced strength and stability of the moulded parts. It also allows for high repeatability, which is essential for mass production. By standardizing components like lift bars and clamp slots, manufacturers can achieve consistency across multiple products, optimizing the production line.

Selection Criteria for Moulding Skeletons

Selecting the right plastic injection moulding skeleton involves considering the design complexity, material compatibility, and production volume. It's essential to collaborate with experienced mould makers who can refine the mould design through prototyping, ensuring the final product meets the desired specifications.

Integrating with Alibaba.com

Alibaba.com serves as a conduit, connecting buyers with a plethora of suppliers offering diverse plastic injection moulding skeletons. The platform facilitates the discovery of suitable moulding solutions, tailored to the unique needs of each manufacturing project. Buyers can leverage the detailed information provided by suppliers to make informed decisions without the hassle of navigating through promotional content.