Popular in your industry

Related Searches:

Top categories

About plywood form concrete spacer

In the realm of construction, the quest for enduring structures is a constant. The use of plywood form concrete spacers is a testament to this pursuit, marrying functionality with longevity. These spacers, critical in maintaining the integrity of concrete forms, are the unsung heroes that ensure the stability and aesthetic appeal of concrete structures. This guide delves into the world of plywood form concrete spacers, exploring their types, applications, and installation nuances to maximize durability in construction projects. We navigate through the myriad options available on Alibaba.com, offering insights into material selection and maintenance practices that promise to enhance the lifespan of your construction endeavors.

Understanding Plywood Form Concrete Spacers

Form ties are specialized fasteners used in construction to hold two sides of a formwork box or wall securely in place. They are integral to maintaining the form of concrete components during the setting process. Designed for specific on-center spacing, form ties can handle the lateral pressures exerted by wet concrete. After the formwork is removed, these ties can be broken off below the concrete surface, leaving a minor indentation that can be filled and smoothed out, ensuring the concrete's aesthetic integrity is maintained.

These ties are available in various lengths to suit different construction needs and are manufactured with integral heads and either metal or plastic form spreaders. The design of form ties allows for easy locking of lumber or plywood formwork, featuring a nominal 1" breakback. Each tie includes an anti-turn device to ensure it breaks cleanly after use. The material used for form ties is typically Carbon Steel, which may undergo heat treatment to enhance strength and may be galvanized or painted to offer some degree of corrosion protection.

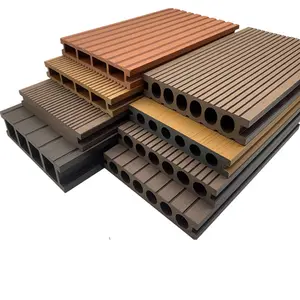

Types of Plywood Form Spacers Available on Alibaba.com

Alibaba.com offers a diverse range of plywood form spacers designed for concrete applications. Among the types available, the Concrete Formwork Board is a versatile option, which is known for its robustness in various construction scenarios. Another type is the Turnbuckle Form Aligner Brace, an adjustable alignment tool that ensures precision in concrete steel and plywood forming processes.

For those seeking durability, the film-faced plywood presents a hardwood core with phenolic glue, suitable for demanding shuttering tasks. This film-faced plywood is engineered to withstand the rigors of construction. The building template plywood, available in various thicknesses, serves as a reliable building template for shuttering formwork.

Builders looking for water-resistant solutions can opt for the Reusable Water-Proof Film-Faced Building Construction Formwork Plywood. This product promises enhanced longevity in wet conditions. Additionally, formwork accessories, including wall bracing and turnbuckle form aligners, are essential for maintaining structural integrity.

Alibaba suppliers provide plywood formwork wood panels and spacers, alongside flat ties, which are integral for concrete wall applications. The Plywood Metal Spacer and Wall Tie cater to panel formwork needs, ensuring a secure and stable setup.

Lastly, the Construction Formwork Plywood Forming System features tie brackets and steel ply spacers, highlighting the importance of a reliable connection between materials. For cost-effective options, the form concrete spacer and marine plywood offer practical solutions for various construction requirements.

Key Applications in Construction

Plywood form concrete spacers, commonly known as shuttering, play a crucial role in various construction scenarios. These spacers are integral to creating robust and accurate molds for pouring concrete, essential for ensuring structural integrity and precision. They are utilized in different parts of building construction, such as roof shuttering, concrete stairs formwork, and general building shuttering. Additionally, their versatility extends to specialized applications like tunnel formwork, where they facilitate the construction of tunnels or other curved concrete structures. The adaptability of plywood form concrete spacers to different shapes and sizes makes them suitable for both circular concrete forms and square concrete column forms, showcasing their importance in a wide array of construction projects.

Features and Specifications

The Spacer Flat Tie is a specialized component designed for plywood formwork construction, offering a blend of strength and adaptability. These spacers are crafted from steel, ensuring they can withstand significant pressure and maintain the integrity of the formwork. Available in a variety of sizes, they cater to different wall thicknesses, with lengths ranging from 10cm to 150cm to accommodate various construction requirements.

The material used for these spacers is typically Q195 steel, a designation that refers to the steel's quality grade, which is crucial for ensuring the durability and reliability of the formwork. To enhance their longevity and resistance to the elements, these flat ties can be galvanized, providing an additional layer of protection against corrosion, or they can be left in their natural state, depending on the specific needs of the construction project.

Material Selection for Enhanced Durability

For enhanced durability in construction, the selection of materials is paramount, particularly when it comes to plywood form concrete spacers. Plyform panels, designed for concrete-forming applications, are a prime example of durability-focused products. These panels often come pretreated with release agents to aid in stripping and are available in various grades, including basic B-B and those with overlays like Medium-density Overlay (MDO) and High-density Overlay (HDO).

The overlays on these panels, made from resin-impregnated cellulose fiber sheets, contribute to their stability, abrasion resistance, and provide a more durable forming surface. HDO panels, in particular, contain a higher resin content, making their surfaces harder and more impervious to water and impacts. This translates to a greater number of reuses and a smoother finish on the concrete surface.

MDO panels, while not as durable as HDO, offer a balance between longevity and cost-effectiveness, with the potential for multiple uses. For further enhancement, B-B and B-C panels can be treated with coatings such as polyurethane or other liquid surface treatments to increase moisture resistance and durability. The phenolic surface film extends the life of the panels.

It's crucial to ensure that the plywood form spacers selected are intended for concrete formwork, as not all overlaid panels are suitable for this purpose. The APA trademark on panels can guide buyers in identifying the grade and type of panel appropriate for their construction needs, ensuring a durable and cost-effective solution for concrete formwork.

Advantages of Using Quality Spacers in Construction

Concrete spacers, including those made from plywood forms, play a crucial role in maintaining the integrity and durability of reinforced concrete structures. They ensure a consistent and optimal distance between the reinforcement bars and the concrete's surface, which is vital for the structure's stability. The uniform separation provided by these spacers is essential for protecting the rebar from corrosion and for ensuring that the load is evenly distributed across the concrete, contributing to the overall longevity of the construction. Furthermore, the use of spacers helps in achieving the required concrete cover, which is a significant factor in safeguarding the reinforcement steel from environmental factors and in maintaining the structural health. Spacers, especially designed for heavy-duty applications, support and space heavy loads, which is critical in large-scale construction projects where the strength and safety of the structure are paramount.

Installation Tips for Maximum Efficiency

For efficient installation of plywood form concrete spacers, it's crucial to start with precise truss spacing, ensuring that each truss is positioned exactly 24 inches on center. Utilize the plywood's inherent sizing, which is typically designed for spacing, to maintain uniformity across the structure. When laying out trusses, the initial mark should be offset by 23 1/4" or 24 3/4" from the framing edge, not the sheathing, to allow for sheet alignment on the truss centers. As you progress, keep a keen eye on the spacing between sheets on the trusses; a small deviation can accumulate over a distance, potentially disrupting the alignment.

Incorporate the use of 'H' edge supports, which are intended for horizontal joints, to clip the plywood sheets together, providing a more secure and less bouncy surface. This also aids in the prevention of nail pops and facilitates a smoother installation process. Vertical joints should align directly over rafters for optimal support. Bracing is another critical step; it should be done immediately after truss installation to prevent any movement that could affect the spacing or stability. Bracing ensures that the trusses maintain their position and facilitates a safer working environment.

Lastly, before sheathing, ensure all bracing, blocking, and uplift connectors are in place. This proactive approach not only streamlines the installation process but also eliminates the need for cumbersome adjustments post-sheathing. By following these guidelines, the installation of plywood form concrete spacers can be executed with maximum efficiency, contributing to the overall durability and integrity of the construction project.

Maintaining and Storing Plywood Form Spacers

Maintaining the integrity of plywood forms used as concrete spacers is crucial for their longevity and effectiveness. One key aspect is the way they are stored. As gleaned from woodworking experts, plywood or similar sheet materials are prone to warping if not stored correctly. To prevent this, it's advisable to store plywood forms in a manner that allows air to circulate freely on both sides.

The use of spacers is a practical solution. These can be fashioned from scrap materials such as wood and a flexible strap material like leather, vinyl, or heavy cloth. The spacers are placed between the plywood forms to maintain a gap, ensuring that flat sheets remain flat over time. For optimal storage, it's recommended to use multiple sets of spacers for each sheet, positioned at the ends and the middle, to support the entire surface area and facilitate ease of access.

This method not only helps in keeping the plywood forms straight and usable for longer periods but also makes them easier to handle and move when needed. By adopting these simple yet effective storage techniques, the durability and functionality of plywood form concrete spacers can be significantly enhanced.

Buying Guide: Sourcing from Alibaba.com

When sourcing plywood form concrete spacers from Alibaba.com, buyers will encounter a diverse range of options suitable for various construction needs. Alibaba's selection includes formwork boards that are comparable to established systems, offering a familiar and reliable solution for formwork requirements. The platform also features adjustable alignment construction accessories made from materials such as concrete, steel, and plywood, ensuring versatility for different project specifications.

The plywood formwork available on Alibaba includes products like formwork concrete with a hardwood core and phenolic glue, providing a durable and reusable solution for shuttering applications. Film-faced plywood options are also listed, which are designed to be water-proof and suitable for multiple uses in building construction, highlighting the emphasis on durability and cost-effectiveness.

For specialized applications, Alibaba.com offers formwork accessories such as wall bracing, turnbuckle form aligners, and various types of spacers and ties, essential for creating precise and secure formwork structures. The platform's inventory is sourced from various manufacturers, ensuring a broad selection for buyers to choose from.

In summary, Alibaba.com provides a comprehensive catalog of plywood form concrete spacers and related accessories, catering to a wide array of construction requirements. The platform's offerings underscore the importance of material quality and product variety, allowing buyers to find the right tools for their construction projects with ease.

Conclusion

The journey through the intricacies of plywood form concrete spacers reveals a landscape where precision meets durability. Snap Ties, formwork boards, and Spacer X Flat Tie emerge as pivotal components in maintaining the form and integrity of concrete structures. Alibaba.com stands as a crucial resource, providing a plethora of options tailored to diverse construction needs. The selection of materials, from steel to phenolic surface film, underscores the commitment to durability. Proper installation and storage practices further cement the longevity of these spacers. In essence, the conscientious use of quality plywood form spacers is not just a choice but a cornerstone in the edifice of modern construction, ensuring that the structures we build stand the test of time and elements. This guide serves as a comprehensive manual for professionals seeking to enhance the resilience and precision of their construction projects through the judicious selection and application of plywood form concrete spacers.