Compact Density Fiberboard Sheets 3mm Thickness With E2 Formaldehyde Emission Standards Fiberboard Compact Density Fiberboard

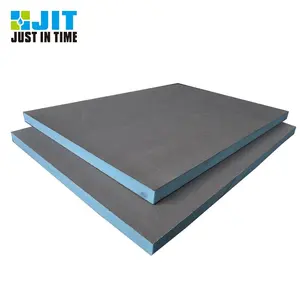

Xps Thermal Insulation Board High Density Thermal Insulation Extruded Polystyrene XPS Foam Wedi Board

Pressed fiberboard, a versatile and cost-efficient material, is widely utilized in the construction of furniture and various surfaces. This engineered wood product is crafted through the compression of wood fibers, which results in a uniform and stable panel. Pressed fiberboard is known for its ease of use in a multitude of applications, from insulation to furniture-making.

Pressed fiber board comes in various densities, each suited to different uses. Low-density fiberboard is often chosen for prefabricated furniture pieces due to its sturdiness and cost-effectiveness. Medium-density fiberboard (MDF) and hardboard represent more luxurious options, offering a balance between durability and aesthetic appeal. These materials are frequently selected for crafting cabinets, desks, and chairs, with the added benefit of a solid wood veneer for an upscale finish.

The adaptability of pressed fiberboard is one of its most significant advantages. It accepts paint exceptionally well, allowing for a wide range of color options, from the understated elegance of black fiberboard to the bold statement of red fiberboard. Furthermore, specialized variants like fire retardant MDF and waterproof fiberboard cater to specific environmental needs, ensuring safety and longevity in kitchen, bathroom, and basement installations.

In response to the growing demand for sustainable building materials, pressed fiber board is also available in eco-friendly versions. These are manufactured from secondary raw materials such as bamboo, sugarcane, hemp, and recycled wood fibers. These green alternatives maintain the strength and durability of traditional fiberboard, making them a responsible choice for environmentally conscious projects.

For areas requiring enhanced safety features, options like fire retardant MDF are available, providing extra protection against potential fire hazards. In contrast, waterproof fiberboard is engineered to withstand the challenges of moisture-prone areas, ensuring that the integrity of the material remains uncompromised in humid conditions.

Suppliers can stock a comprehensive range of pressed fiberboard to meet the diverse needs of the market. By purchasing in bulk, suppliers can maintain an adequate supply to fulfill large orders, ensuring that projects can proceed without delay. A wide selection of colors and types, including plain MDF and various colored fiberboards, allows for customization according to customer preferences.