Introduction to Profile Pipe Hole Cutting Machines

The realm of construction, hardware, and automobile industries is continually evolving, with profile pipe hole cutting machines playing a pivotal role in these advancements. These machines are designed to create precise holes in various types of pipes, facilitating a multitude of applications across diverse sectors.

Types and Applications

When selecting a pipe hole cutting machine, one can choose from fully automatic to semi-automatic models, each catering to different operational scales and requirements. The fully automatic variants are particularly suited for larger industries with high production demands, while semi-automatic machines offer flexibility for smaller-scale operations. These machines are adept at handling a range of materials, from copper and stainless steel to aluminum alloys, making them indispensable in metalworking tasks.

Technical Specifications

The technical prowess of a pipe cutting machine is evident in its capacity to cut through varying thicknesses, typically 5mm to 20mm, and accommodate cutting diameters from 6mm to an impressive 220mm in larger models. The choice between laser technology and blade cutters adds to the versatility, with laser machines boasting powers around 1,000w and blade machines compatible with sizes from 250mm to 450mm.

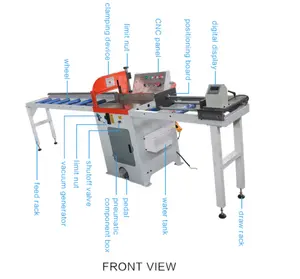

Operational Features

Advanced pipe hole cutting equipment harnesses the precision of PLC or CNC control systems, transcending the limitations of manual operation. These machines are not only capable of cutting standard shapes but can also execute complex patterns with ease. Furthermore, the inclusion of automated pipe loading and water cooling systems in fully automatic machines streamlines the production process.

Machine Build and Power Consumption

The build of these machines ranges significantly, with weights from a manageable 100kg to a robust 5,000kg, reflecting the diversity in their operational scale. Smaller machines are compatible with two-phase power lines, whereas larger, more power-intensive models require three-phase power, highlighting the importance of matching the machine's power requirements with the available infrastructure.

Choosing the Right Machine

In the quest for the ideal pipe profile cutting machine, it is crucial to consider the specific needs of your operation, including the type of metal, pipe shape, and production volume. With a comprehensive selection available, these machines can cater to round or square pipes, solid or hollow, ensuring that your specific cutting requirements are met with precision.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4