Popular in your industry

Related Searches:

Top categories

About rail grinding and deburring machine

Rail Grinding and Deburring Machines: An Overview

Rail grinding and deburring machines are specialized equipment used in the maintenance of railway tracks. These machines serve a critical role in extending the life of rail tracks, ensuring smooth and safe train operations. The category encompasses various models designed to handle different rail conditions and defects.

Types and Applications

The variety of rail grinding and deburring machines includes portable units for on-site maintenance and larger, stationary machines for extensive rail care. These machines are utilized in several applications, from correcting rail surface defects to precise shaping of rail profiles. Their use is essential in maintaining optimal contact between the rail and train wheels, contributing to the safety and efficiency of rail transport.

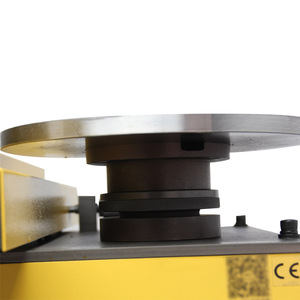

Features and Materials

Constructed from durable materials such as hardened steel and industrial-grade stainless steel, these machines are built to withstand the rigors of rail maintenance work. Features may include ergonomic controls, dust collection systems, and advanced grinding and deburring capabilities, which are crucial for achieving a smooth rail surface.

Advantages of Modern Rail Maintenance Equipment

Modern rail maintenance equipment like grinding and deburring machines offer significant advantages. They reduce the need for manual labor, increase precision in rail shaping, and help in the early detection of rail defects. This proactive maintenance approach can prevent costly rail replacements and minimize service disruptions.

Materials Used in Rail Grinding and Deburring

The materials used in the construction of rail grinding and deburring equipment are selected for durability and performance. High-grade metals ensure that the machines can perform under the stress of grinding hard rail steel, while components like grinding wheels are often made from composite materials designed for longevity and effective grinding.

Choosing the Right Machine for Your Rail Maintenance Needs

Selecting the appropriate rail grinding and deburring machine depends on various factors, including the extent of rail damage, the precision required, and the scale of the maintenance project. It is crucial to assess the specifications of each machine to ensure it meets the specific needs of your rail maintenance tasks.