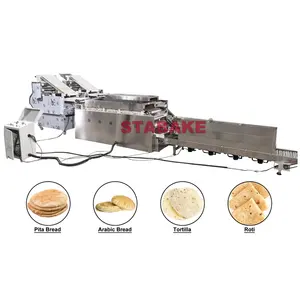

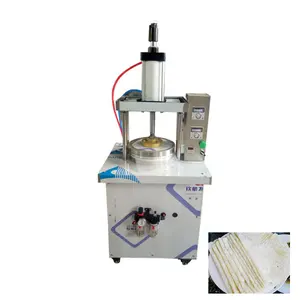

Revamp your kitchen or business with these cutting-edge and innovative roti bread that come with unrivaled discounts on Alibaba.com. The roti bread utilize the most advanced inventions and technologies to assemble desirable attributes for your needs. They are made from sturdy materials that ascertain long lifespans and efficient performance over long durations. The roti bread make the process of producing grain products extremely timesaving and productive.

The roti bread come in a wide variety of makes and traits that takes several considerations for individuals and group requirements. Their top-quality performance is guaranteed by having processing lines that are already featured by renowned roti bread suppliers and distributors. The roti bread are loaded with powerful parts that are highly effective even when consuming low electric currents to help you save on your electricity bills. Take advantage of the different models and sizes that allow you to keep them anywhere in your facility.

When exploring Alibaba.com, you’ll realize that these roti bread are very affordable, especially with their unique promotion deals. Their cost of maintenance is also unbelievably low because their spare parts are readily available and repair is easy. The roti bread are supplied with user guidelines to promote optimal operations and safety measures. Nevertheless, you may request on-field installation from the roti bread sellers and any other clarifications you may require.

Make the right call and improve productivity in your home or business. Explore the wide range of roti bread available on Alibaba.com and discover how much you can save. Customization requests regarding logos and unique prints are allowed.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4