Rubber Solution Making Machine Overview

The rubber solution making machine is a pivotal component in the rubber production industry, designed to cater to the creation of various rubber products. This machinery encompasses a range of devices, from mixers and presses to bale cutters, each serving a specific function in the rubber solution preparation process. The versatility of these machines allows for the production of a wide array of rubber items, from industrial components to everyday goods.

Types and Applications

There are several types of rubber processing machinery, including those for making rubber bands, silicone products, and rubber mats. Each type serves a unique purpose, with specific machines tailored for producing elastic rubber materials or rubber sheets. The application of these machines spans across various industries, highlighting their importance in manufacturing processes that require rubber as a key material.

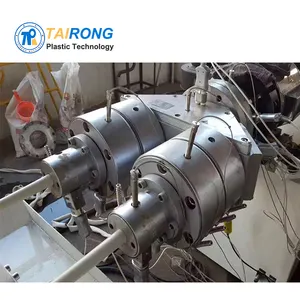

Technical Features and Materials

The rubber manufacturing equipment is engineered with features such as hot compress functions, vulcanization capabilities, and fully automatic two-layer mold styles. These machines are constructed using durable materials like nickel-chromium alloy, ensuring resistance to rust and extending the equipment's lifespan. The technical sophistication of these machines is evident in their collaborative circuit designs, which facilitate ease of operation and maintenance.

Customization and Innovation

Innovation is at the forefront of rubber production machinery design. With the ability to customize based on structural requirements, businesses can opt for machines with double working stations, vertical configurations, or specific clamping forces. This level of customization ensures that the machinery aligns with the unique demands of different production lines.

Advantages of Modern Machinery

Modern rubber solution making machines offer significant advantages, such as increased efficiency and precision in rubber product manufacturing. The integration of advanced technologies in these machines reduces manual labor and streamlines production processes, leading to enhanced productivity for businesses.

Connecting with Suppliers

Alibaba.com serves as a gateway for businesses to connect with a multitude of suppliers offering a variety of rubber solution making equipment. These suppliers are equipped to discuss the specific needs of a business and provide suitable machinery options, both new and used. For further information on machinery specifications and to explore solutions that align with your production requirements, reaching out to suppliers via Alibaba.com is a recommended step.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4