Introduction to Sand Casting Molding Machines

Sand casting molding machines are integral to the metalworking industry, facilitating the formation of metal components by shaping molten metal within a die. This process is pivotal for creating a myriad of items, ranging from simple tools to complex machinery parts. The versatility of sand casting equipment allows for the production of castings in various sizes and complexities, catering to a broad spectrum of industrial applications.

Types and Applications

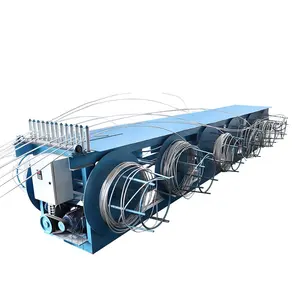

The diversity of foundry molding machines encompasses a range of types, each suited to specific tasks. From automatic sand molding machines that enhance production efficiency to portable sand casting machines offering flexibility in location, the selection is vast. These machines serve numerous sectors, including automotive, aerospace, and construction, where the precision and integrity of metal components are non-negotiable.

Features and Materials

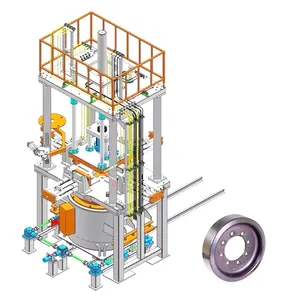

Metal casting machinery is designed with features that ensure operational efficiency and reliability. The construction of these machines often involves robust materials capable of withstanding high temperatures and the rigors of industrial environments. Components of a sand casting molding machine typically include impression devices, clamping units, and dies, all engineered to work in unison for optimal casting results.

Advantages of Sand Casting Machines

Utilizing a sand molding machine in metal casting processes offers several advantages. These machines provide the ability to produce complex shapes with a high degree of accuracy and repeatability. Moreover, the flexibility in terms of size and material types makes sand casting a preferred method for custom metalwork. The adaptability of these machines to different metals, such as aluminum and zinc, further extends their utility across various casting projects.

Specifications and Performance

When selecting a sand casting molding machine, it is crucial to consider the specifications that align with your business needs. Factors such as size, power, and capacity play a significant role in the machine's performance and the quality of the final product. Suppliers on Alibaba.com offer a spectrum of machines, each with detailed specifications to aid buyers in making an informed decision.

Choosing the Right Machine

For businesses seeking to invest in industrial casting equipment, Alibaba.com presents a comprehensive collection of machines. Suppliers are available to assist with inquiries, providing information on machinery that aligns with your casting requirements. It is advisable to request information on the various models to ensure the equipment selected will meet the demands of your specific metal casting processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4