Popular in your industry

Related Searches:

Top categories

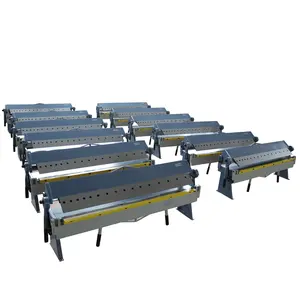

About sheet metal pan box brake

A sheet metal pan box brake is a specialized piece of machinery used in the metalworking industry for forming and bending sheet metal into specific shapes. This equipment is designed to accurately bend sheet metal at predetermined angles, making it a vital tool in various manufacturing and fabrication processes. The box and pan brake can be used to create various structures, including ductwork, enclosures, and other components that require precise bending of sheet metal. It is widely used in industries such as HVAC, automotive, aerospace, and general manufacturing.

Components of a sheet metal pan box brake

The pan and box brake consist of a bed or bed and apron, a clamping beam, and a bending leaf. The bed, also known as the bed and apron, is the flat surface on which the sheet metal rests during the bending process. The clamping beam secures the sheet metal in place to prevent it from moving during bending. The bending leaf is the upper part of the machine that exerts pressure on the sheet metal to bend it. Some models may also have a counterweight mechanism to assist in bending thicker or heavier sheet metal. The box pan brake may also include various features such as adjustable fingers or stops for precise bending, scales or indicators for measuring bend angles, and a removable apron for bending box shapes.

Types of sheet metal pan box brake

The box and pan metal brake can be categorized based on their size, capacity, and the mechanism used to perform the bending operation. The size of a pan and box brake refers to the length of the bending bed or the maximum width of the sheet metal it can accommodate. Small benchtop models are suitable for light-duty applications and smaller workpieces, while larger floor-standing machines are designed for heavier and more extensive sheet metal bending. The capacity of a box and pan brake typically refers to the maximum thickness of the sheet metal it can bend. Common capacities range from 18 gauge to 10 gauge, with heavier-duty models capable of bending even thicker materials. The mechanism used in a pan and box brake to perform the bending operation can be categorized into manual, mechanical, and hydraulic types. Manual box and pan brakes rely on the operator's physical force to bend the sheet metal, making them suitable for light-duty applications. Mechanical box and pan brakes use a mechanical lever or cam system to multiply the operator's force, allowing for easier bending of thicker materials. Hydraulic box and pan brakes utilize hydraulic cylinders to apply significant bending force, making them ideal for bending heavy or high-strength materials. There are also different subtypes of a box and pan brake, such as straight brakes, cornice brakes, leaf brakes, and press brakes, each with specific features and applications.

Applications of sheet metal pan box brake

The sheet metal pan box brake offers several advantages in terms of efficiency, accuracy, and versatility. The ability to create complex shapes and structures, such as boxes, enclosures, and channels, makes it a valuable tool in various industries. The precise bending capability ensures that the finished components meet the required specifications, reducing material waste and rework. Additionally, the box and pan brake's versatility allows for quick setup and adjustment, making it suitable for both high-volume production and custom fabrication projects. The box and pan brake is commonly used in manufacturing processes that involve the production of metal components with intricate shapes, such as the fabrication of electrical enclosures, metal cabinets, and HVAC ductwork. In the automotive industry, the box and pan brake is used to create body panels, brackets, and other structural components. The aerospace sector relies on the box and pan brake to manufacture aircraft components, including panels, frames, and structural elements. The box and pan brake is also a crucial tool in the production of furniture, appliances, and other consumer goods that require precise bending of sheet metal. In the construction industry, the box and pan brake is used to fabricate architectural elements, metal cladding, and roofing components. The versatility and accuracy of the box and pan brake make it an indispensable tool in various metalworking applications across different industries.