Introduction to Spray Dryer Technology

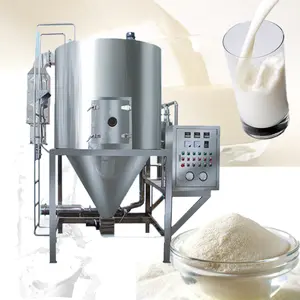

Spray drying is a pivotal process in various industries, and spray dryer Malaysia represents a category of this essential equipment tailored for a multitude of drying applications. This technology is instrumental in converting liquid solutions, suspensions, or emulsions into dry powder form by rapidly drying with a hot gas.

Types and Applications

The versatility of spray dryer machine Malaysia is evident in its wide range of types designed to meet specific industry needs. From small-scale laboratory units to large industrial systems, these dryers serve critical roles in food production, pharmaceuticals, and chemical processing, among others. Their applications extend to drying of food products, pharmaceutical agents, and industrial chemicals, showcasing their adaptability to different operational scales and requirements.

Features and Materials

Spray dryers in Malaysia are engineered with features that cater to efficient and consistent drying processes. They are constructed from robust stainless steel, ensuring durability and resistance to corrosion. The design often includes advanced dehumidifying systems, capable of handling various materials with precision. This ensures that the drying process is not only effective but also retains the quality of the products being processed.

Advantages of Spray Drying

The advantages of utilizing a spray dryer in Malaysia are numerous. These machines offer a rapid drying process, which is essential for preserving the quality and functionality of heat-sensitive materials. Additionally, the spray drying technique ensures uniform particle size distribution, which is crucial for industries where consistency is key. The process is also scalable, making it suitable for both small-scale and large-scale production.

Customization and Efficiency

In the realm of industrial drying, the need for customization is paramount. Malaysia spray dryer units are customizable to fit specific process requirements, allowing for adjustments in temperature, feed rate, and particle size. This level of customization ensures that the drying process is as efficient as possible, leading to enhanced productivity for businesses.

Choosing the Right Spray Dryer

Selecting the appropriate spray dryer machine in Malaysia involves understanding the specific needs of your operation. Factors such as capacity, material characteristics, and desired end-product qualities are crucial in determining the right model. With a range of spray dryers available, it is important to consider the technical specifications and how they align with your processing goals.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4