Introduction to Steel Rule Notchers

Steel rule notchers are specialized tools used in the die-making process, particularly for cutting precise notches in steel rule dies. These dies are essential components in the die-cutting industry, where accuracy and consistency are paramount. A steel rule notcher is designed to create notches of specific sizes and shapes, which are crucial for the bending process in die construction.

Types and Applications

There are various types of steel rule notchers, each serving a unique purpose in the die-making field. Manual notchers offer simplicity and control, while hydraulic notchers provide power for thicker materials. Pneumatic notchers combine speed with ease of use, and automatic notchers are used for high-volume tasks. These tools are applied in industries ranging from packaging to automotive, where precision die-cutting is required.

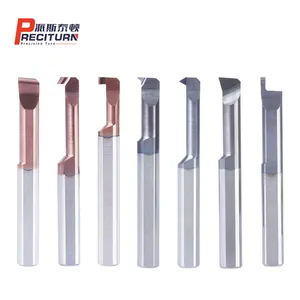

Features and Materials

A steel rule notcher is characterized by its robust construction and precision engineering. Typically made from durable metals, these notchers are built to withstand the rigors of industrial environments. The cutting components are often crafted from hardened tool steel, ensuring longevity and consistent performance. Advanced models may feature adjustable angles and depths to accommodate various die designs.

Advantages of Using a Steel Rule Notcher

Utilizing a steel rule notcher in die-making brings several advantages. It enhances the precision of die edges, which is critical for accurate die-cutting. The efficiency of the notching process is also improved, saving time and reducing waste. Moreover, the versatility of these tools allows for their use with a range of materials, from thin foils to thicker plastics.

Selection Considerations

When selecting a steel rule notcher, it is important to consider the material thickness, the type of notches required, and the volume of production. The tool's compatibility with existing die-making equipment and the specific requirements of the intended application should also be taken into account.

Maintenance and Durability

Maintaining a steel rule notcher involves regular cleaning, lubrication, and inspection of cutting edges. Proper care ensures the tool operates at peak efficiency and extends its service life, making it a reliable component in the die-making process.

steel rule notcher

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4