Popular in your industry

Related Searches:

Top categories

About table polish machine

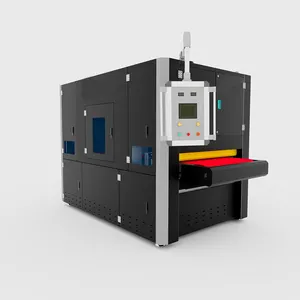

Introduction to Table Polish Machines

Table polish machines are essential tools in various industries, designed to enhance the finish of metal surfaces. These machines are adept at removing imperfections such as rust, oxide layers, and scratches, leaving behind a smooth and refined surface. The versatility of table polish machines makes them suitable for a range of applications, from large-scale industrial use to precise laboratory research.

Types and Technologies

The technology behind table buffing machines varies to accommodate different materials and sizes. For elongated steel pipes, heavy-duty polishers with substantial weight and power are employed, ensuring a consistent and efficient polishing process. Conversely, smaller and irregularly shaped metals benefit from the agility of vibratory polishing machines, which utilize various media to achieve a lustrous finish.

Applications Across Industries

Table polish machines are instrumental across diverse sectors. In the automotive and aerospace industries, they are used to polish components to precise specifications. The medical field also relies on these machines for the finishing of surgical instruments. For research purposes, metallographic polishers are invaluable in preparing samples to study metal structures.

Features and Specifications

These machines come with adjustable features, such as multi-wheel head polishers that cater to different pipe dimensions. The polishing speed can be regulated, with some machines offering speeds from 20m/min to 32m/min. For intricate tasks, metallographic polishers provide variable rotational speeds and come equipped with multiple polishing wheels.

Materials and Mediums

The construction of table polish machines is designed to handle a variety of metals. Vibratory machines, for instance, use specific mediums that work in tandem with the machine's vibrations to polish metals effectively. The choice of medium is crucial, as it directly impacts the quality of the polish.

Advantages of Modern Polishers

Modern table buffing machines offer significant advantages in terms of efficiency and adaptability. They are capable of accommodating a wide range of metal types and shapes, ensuring a high-quality finish. The automation of these machines also allows for continuous operation, which is beneficial for high-volume polishing tasks.