Popular in your industry

Related Searches:

Top categories

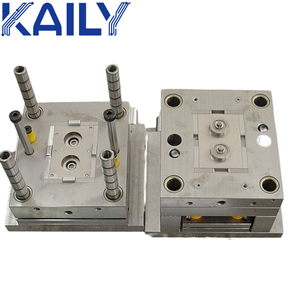

About the mould for cup making machine

Introduction to Cup Moulding Machines

The landscape of industrial manufacturing has been revolutionized by the advent of specialized machinery, particularly the mould for cup making machine. These machines are pivotal in the production of plastic cups, serving a myriad of sectors from food and beverage to healthcare. This introduction delves into the intricacies and applications of cup moulding machines, highlighting their significance in modern production lines.

Types and Applications

Cup moulding machines come in various designs, each tailored to meet specific production needs. From thermoforming machines to injection moulding units, the diversity in this category ensures that manufacturers can select the perfect machine to suit their output requirements. These machines are instrumental in producing cups for various applications, including disposable drinkware, packaging solutions, and medical containers.

Operational Features

The operational prowess of cup moulding equipment lies in its ability to efficiently transform raw materials into finished products with precision. Equipped with advanced technology, these machines facilitate operations such as cutting, shaping, and forming with ease. Their automated functions not only enhance production speed but also ensure consistency in product quality.

Material Compatibility and Efficiency

Modern cup moulding machines are compatible with a range of materials, including PP, PET, and polystyrene, allowing for a versatile production process. The efficiency of these machines is evident in their energy consumption rates, which are designed to be economical, thereby reducing operational costs while maintaining high productivity levels.

Advantages of Advanced Moulding Machines

The advantages of utilizing advanced cup making mould machines are manifold. These machines are designed to minimize labor costs by automating complex processes, allowing for a reduction in manual intervention and a consequent increase in safety and efficiency. Furthermore, the precision engineering involved in these machines ensures minimal waste production, aligning with sustainable manufacturing practices.

Customization and Adaptability

Flexibility is a key feature of plastic cup moulding machines, with options for customization to meet specific production demands. Manufacturers can adapt these machines to their existing production lines with ease, ensuring seamless integration and scalability. This adaptability extends to the production of cups in various shapes and sizes, catering to a broad spectrum of market demands.

In conclusion, the mould for cup making machine represents a critical investment for manufacturers looking to streamline their production processes and scale their output. While exploring the range of machines available on Alibaba.com, buyers can find units that align with their operational needs and production goals, without the constraints of brand endorsements or promotional biases.