Popular in your industry

Related Searches:

Top categories

About tie bar molding machine

Introduction to Tie Bar Molding Machine

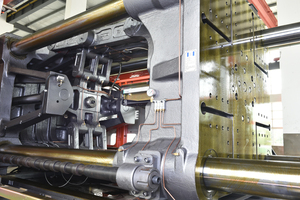

A tie bar molding machine is a crucial piece of equipment in the manufacturing industry, specifically in the production of plastic parts through injection molding. This machine plays a vital role in holding the mold halves together during the injection and cooling processes. The tie bars ensure the mold remains closed with the necessary force to prevent any flash or parting lines on the final product.

Technical Specifications and Design

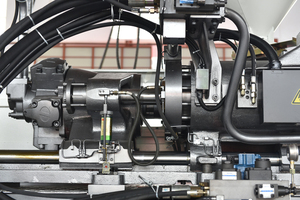

The tie bar molding machine typically consists of sturdy steel tie bars that connect the movable platen and the stationary platen of the injection molding machine. These tie bars are precision-engineered to withstand high clamping forces, ensuring the mold remains securely closed during the injection process. The length and diameter of the tie bars vary depending on the machine's tonnage capacity and the size of the mold being used.

Advantages of Tie Bar Molding Machines

One of the key advantages of tie bar molding machines is their ability to provide uniform clamping force across the entire mold surface, resulting in consistent part quality. Additionally, these machines offer enhanced stability and precision during the injection process, leading to minimal part defects and scrap rates. The robust design of tie bar molding machines also contributes to their longevity and reliability in high-volume production environments.

Features of Injection Molding Machine Tie Bars

Injection molding machine tie bars come in various designs to accommodate different mold configurations and production requirements. Some machines feature hydraulic clamping systems for more precise control over the clamping force, while others utilize electric or mechanical systems. The surface finish of the tie bars is often optimized to reduce wear and friction, ensuring smooth operation over prolonged use.

Choosing the Right Tie Bar Molding Machine

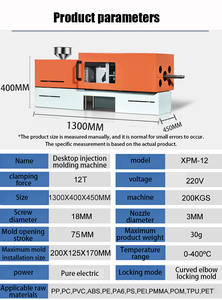

When selecting a tie bar molding machine for your manufacturing needs, consider factors such as the machine's tonnage capacity, tie bar spacing, and compatibility with your existing molds. Assessing the required clamp force and shot size will help determine the most suitable machine for your production processes. It is also essential to evaluate the machine's energy efficiency and automation capabilities for optimized performance.

Maintenance and Care of Tie Bar Molding Machines

To ensure the longevity and performance of your tie bar molding machine, regular maintenance is crucial. Routine inspections of the tie bars, lubrication of moving parts, and monitoring of hydraulic systems are essential tasks to prevent unexpected downtime and ensure consistent production output. Proper care and maintenance will extend the machine's lifespan and uphold product quality standards.