Automatic Tissue Machine CD-2000II Full Automatic Baby Wet Wipes Machine Wet Tissue Machine

Manual Corrugated Paper Die Cutter And Creasing Machine / Die Cutter Machine/ Box Making Machine

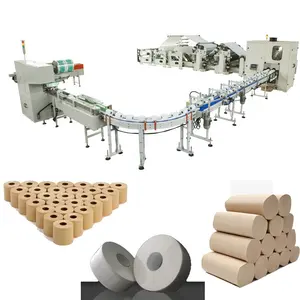

Tissue Paper Machine Manufacturer Complete Set Big Jumbo Roll Toilet Paper Machine Tissue Paper Making Machine Production Line

Automatic Corrugated Board Die Cutting And Stripping Machine Production Line

Baby Wipes Machine Price Top Supplier Softly Non-woven Fabric Acceptable Price High Quality Baby Wipe Wet Tissue Making Machine Price

Creasing And Die-Cutting Machine Creasing And Die Cutting Machine Paper Die Cutting Machine

small scale second hand tissue toilet paper mill rolls making machine in pakistan

small scale dry tissue toilet paper mill rolls making machine in Pakistan

Hot selling customized tissue paper machine price in pakistan Quality Choice

Paper Mill Production Line Tissue Paper Machinery In Pakistan

Soft napkin tissue paper making machine price in pakistan

1760mm paper making machine to make toilet tissue paper price in pakistan with best price

Henan youngbamboo fully automatic facial tissue paper making machine tissue paper machine price in pakistan

Full automatic 2/3 lines tissue paper machine production price in pakistan

small scale second hand tissue toilet paper mill rolls making machine in pakistan

Great Variety Recycling Tissue Paper Roll Making Machine Production Price In Pakistan

787 small straw bamboo recycled toilet tissue paper product making machine price in pakistan

1 ton jumbo roll tissue paper machine price in nigeria

fully automatic 1-3 ply embossed toilet tissue paper roll making machine price in Pakistan

small scale tissue toilet paper mill rolls making machine in pakistan

Cost Of Tissue Paper Napkin Making Machine Automatic Price In Pakistan For Sale

OCC Complete Paper Machine Plant Kraft Tissue Toalet Paper Machine Price in Pakistan USA Taiwan Machinery China Manufacture

Bathroom Tissue Paper Making Machine Price in Pakistan Fully Automatic 200 M/min Production Capacity Toilet Tissue 0-200m/min

5 Ton Per Day Tissue Paper machinery tissue paper mill in pakistan

Factory Price Automatic Sanitary Napkin Folding Machine Tissue Paper Machine Price In Pakistan Sanitary Napkin Folding Machine

Fexik Brand Tissue Paper Manufacturing Making Machine Price in Pakistan

Tissue paper making machine price in pakistan paper making machine price in india small tissue paper making machine automatic

small scale second hand tissue toilet paper mill rolls making machine in pakistan

Full automatic tissue paper maker making machine price in pakistan

tissue paper making machine price in pakistan tissue paper making machine toilet machine making paper tissue

Portable Tissue Paper Making MachineTissue Paper Making Machine Price In Pakistan

full automatic china manufacturer multi size tissue paper making machine price in pakistan

1092 Tissue Paper Making Plant Tissue Paper Machine Price In Pakistan

Factory Sale Low Price Tissue Paper Production Line Toilet Paper Making Machine For Sale

Full Automatic Embossing Folding Napkin Tissue Paper Making Machine Paper Napkin Machine

Automatic Paper Core Cutting Machine Production Roll Core Paper Cutter Paper Tube Making Machine for Tubes

Full Automatic Toilet Paper Making Machine Paper Product Making Machinery at Competitive Price

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4