Introduction to Tongue Groove Machines

Tongue and groove joinery is a woodwork technique that involves the interlocking of panels. Central to this method is the tongue groove machine, a specialized tool designed to create the tongue and groove joints efficiently. This machinery is indispensable in the woodworking and carpentry industries, where precision and durability of the joinery are paramount.

Types and Applications

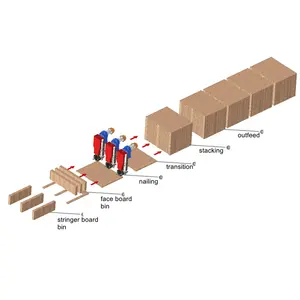

The versatility of tongue and groove machines is evident in their various types, each tailored for specific applications. From manual to automatic models, these machines cater to different production volumes and workshop sizes. They are widely used in the manufacturing of flooring, paneling, and furniture, where secure and seamless joints are essential.

Features and Materials

A tongue groove machine is characterized by features that enhance performance and user experience. Typically constructed from robust materials like cast iron and steel, these machines withstand the rigors of continuous operation. Advanced models boast features such as micro-adjustment capabilities and anti-kickback safety measures, ensuring precise cuts and operator safety.

Advantages of Using Tongue Groove Machines

The adoption of a tongue groove machine in woodworking brings numerous advantages. It elevates efficiency, guarantees uniformity in production, and minimizes material wastage. The precision offered by these machines contributes to the overall structural integrity of the final product, which is crucial in professional woodworking.

Considerations for Selection

Selecting the right tongue groove machine involves considering factors such as the material thickness, the complexity of the projects, and the desired production output. Woodworking professionals should evaluate the machine's compatibility with their existing setup and the types of joints it can produce to ensure it meets their specific needs.

Maintenance and Safety

Maintaining a tongue groove machine in top condition is essential for its longevity. Regular cleaning and adherence to maintenance schedules prevent breakdowns and extend the machine's life. Safety is another critical aspect, with proper training for operators being a must to ensure a hazard-free work environment.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4