Introduction to Topwell Plasma Cutters

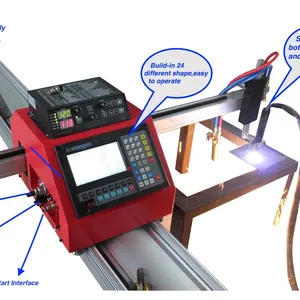

Plasma cutting technology has revolutionized the way industries cut through metal. The Topwell plasma cutter stands out in this category, offering precision and efficiency. This equipment is a staple in environments where metal fabrication is essential, including construction sites, manufacturing plants, and building material shops. Plasma cutters from Topwell are designed to cater to a variety of cutting tasks with their robust plasma power sources and CNC technology.

Types and Applications

The versatility of Topwell plasma cutters is evident in the range of types available. From manual handheld units to fully automated CNC plasma cutters, these machines serve different applications. They are utilized in cutting intricate shapes in metal for construction projects, creating parts in manufacturing processes, and even in artistic metalwork. The adaptability of these cutters makes them suitable for both heavy-duty industrial tasks and precision-based custom work.

Features and Materials

A Topwell plasma cutter is engineered with features that enhance its operational efficiency. The integration of advanced motor systems and pressure vessel technology ensures that these cutters deliver consistent performance. The materials used in the construction of these machines are chosen for durability and resilience, enabling them to withstand the rigors of industrial use while maintaining high precision in cutting tasks.

Advantages of Using Topwell Plasma Cutters

Users of Topwell plasma cutters benefit from a range of advantages. These cutters are designed to be user-friendly, with an emphasis on ease of operation. The multifunctional nature of these machines means they can be adapted to various metal cutting tasks, making them a valuable asset in any workshop. Additionally, the precision offered by Topwell plasma cutters ensures minimal waste and higher efficiency in metal fabrication.

Choosing the Right Topwell Plasma Cutter

Selecting the appropriate Topwell plasma cutter depends on the specific needs of the task at hand. Factors to consider include the type of metal, thickness, and the precision required. While all Topwell cutters are designed to meet a high standard of performance, understanding the specific features of each model can help in making an informed decision without the need for brand endorsements.

Maintenance and Care

Maintaining a Topwell plasma cutter is crucial for its longevity and performance. Regular checks and routine maintenance ensure that the cutter operates at optimal levels. Users should refer to the manufacturer's guidelines for specific care instructions to keep their Topwell plasma cutter in top condition, ensuring reliability and precision in every cut.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4