Popular in your industry

Top categories

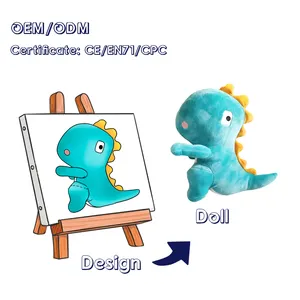

About toy photos

Toys are more than just objects; they are tools for the imagination. The toy photos industry thrives on this principle. It is driven by innovation, creativity, and the desire to bring joy to people. This industry is so vast that there is a toy for every preference and need. Children are the main target, but the industry also caters to adult collectors, artists, and hobbyists. The production of toys is a complex process that involves different materials, technologies, and skills. The following sections will explore some of the most important aspects of the toy photos industry.

Materials used in the toy photos industry

Toys can be made of various materials, including plastic, wood, metal, and fabric. Plastic is one of the most popular choices due to its versatility, durability, and cost-effectiveness. It can be molded into different shapes and colors, enabling the production of a wide range of toys. Wood is another common material, known for its sturdiness and natural appeal. Metal toys are less common but are appreciated for their durability and classic look. Fabric toys, such as plushies, are soft and cuddly, making them popular choices for children. In the toy photos industry, the choice of materials is crucial. The quality and safety of the toys depend on the materials used. For example, plastic toys must be made of non-toxic materials to ensure they are safe for children. The durability of the materials is also important, as toys need to withstand the wear and tear of play.

Technologies used in the toy photos industry

The toy photos industry uses a wide range of technologies to design, produce, and distribute toys. Computer-aided design (CAD) software is commonly used to create 3D models of toys. This technology enables designers to visualize and test their ideas before moving on to production. Injection molding is a popular manufacturing process for plastic toys. It involves injecting molten plastic into a mold cavity, where it cools and solidifies. This process is efficient and cost-effective, making it a preferred choice for mass-producing toys. For wooden toys, traditional woodworking techniques are often used, such as cutting, shaping, and sanding. In recent years, digital technologies like 3D printing have also made their way into the toy photos industry. This technology enables the production of complex and customized toys, expanding the possibilities for toy designers and manufacturers.

Sustainability in the toy photos industry

The toy photos industry is increasingly focusing on sustainability. This involves using eco-friendly materials, reducing waste, and adopting more sustainable production and distribution practices. Many toy manufacturers are exploring alternatives to traditional plastics, such as biodegradable plastics and plant-based materials. These materials are designed to break down more easily in the environment, reducing the impact of plastic waste. Some companies are also implementing recycling programs to give a second life to old toys. Sustainable packaging is another important aspect of the industry. Many companies are moving away from single-use plastics and opting for more eco-friendly options. These efforts are not only driven by environmental concerns but also by consumer demand. Many parents are looking for toys that are safe, durable, and environmentally friendly, reflecting a growing awareness of sustainability.