Popular in your industry

Top categories

About tpm twisted yarn

The term "tpm twisted yarn" is a specialized textile product known for its twists per meter (TPM), which significantly influences the strength, texture, and elasticity of the yarn. This type of yarn is integral in various textile manufacturing processes, offering versatility and durability to the end products. Alibaba.com showcases a diverse range of tpm twisted yarns to meet the demands of global businesses.

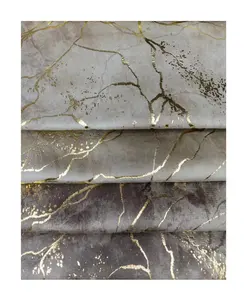

Types and Characteristics of TPM Twisted Yarn

TPM twisted yarn comes in a variety of types, each with unique characteristics that cater to different textile needs. For instance, the Wholesale polyester dty yarn 75d72f Twisted 75D/120T SD OPTICAL WHITE Z TPM weaving yarns are designed for high-end woven labels, offering a glossy finish and resistance to shrinkage. On the other hand, Polyester Twisted Yarn 150D Raw White 120 TPM on Dyeing Tube is preferred for dyeing processes due to its high absorption capacity. The 100-600 TPM twisted polyester filament yarn range provides options for varying degrees of elasticity and strength, suitable for a wide array of applications from fashion to industrial textiles. These yarns are meticulously engineered to maintain their integrity during the rigors of textile processing, ensuring that they contribute to the creation of high-quality final products.

Structure and Operation of TPM Twisted Yarn

The structure of tpm twisted yarn is a marvel of textile engineering. The yarn is composed of multiple polyester filaments, each twisted at a precise rate per meter to achieve the desired strength and texture. The twisting process aligns the fibers, which enhances the yarn's tensile strength and consistency. This structure is crucial for the yarn's performance during weaving, knitting, or other textile production processes, ensuring uniformity and reducing the risk of breakage. The physical components of the yarn, including the raw material input, twist level, and final treatment, all play a role in how it operates within different components of textile machinery, affecting everything from the weaving speed to the final fabric's drape and feel.

Materials and Properties

The primary material used in tpm twisted yarn is 100% polyester, chosen for its exceptional durability, resilience, and ease of maintenance. Polyester's inherent anti-pilling and anti-bacteria properties make it an ideal choice for textiles that require long-term use and frequent handling. Additionally, its ability to retain color and resist shrinkage under various conditions is invaluable for maintaining the quality and appearance of the final textile products. The selection of polyester as the material of choice for tpm twisted yarn is due to its superior performance in textile applications compared to other fibers, providing benefits that are critical in both consumer and industrial textiles.

Business Usages and Applications

In the business realm, tpm twisted yarn is indispensable in the production of garments, home textiles, and industrial fabrics. Its application in embroidery and high-quality sewing threads has revolutionized the apparel industry, allowing for intricate designs and durable seams. In the industrial sector, the yarn's high tenacity makes it suitable for products such as filters, conveyor belts, and safety gloves, where material failure is not an option. The versatility of tpm twisted yarn creates significant business value by broadening the range of products a manufacturer can offer. It also plays a pivotal role in the automotive industry for manufacturing airbags and seat belts, where its strength and reliability are crucial for safety.

Functions of TPM Twisted Yarn

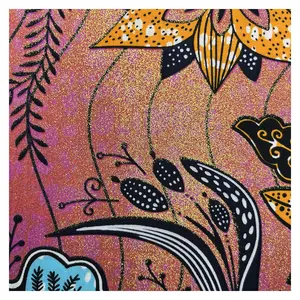

TPM twisted yarn is designed to perform a multitude of functions. It provides structural integrity to fabrics, ensures elasticity where needed, and contributes to the overall aesthetic appeal of textile products. Its ability to be woven into various densities and textures allows for its use in everything from delicate lace to robust upholstery fabrics. The yarn's function extends beyond just the textile industry; it is also used in the production of fishing nets, ropes, and other items that require a high degree of durability and resistance to environmental factors.

Features of TPM Twisted Yarn

The distinct characteristics of tpm twisted yarn include its uniform twist distribution, which results in a smooth, even surface that is less prone to snagging and abrasion. The yarn's moisture-absorbent feature is particularly beneficial for active wear and other garments where comfort and dryness are paramount. These unique selling points set it apart from competitors, making it a sought-after material in the textile market. Additionally, the yarn's ability to be thermally bonded or fused with other fibers opens up possibilities for creating composite materials with enhanced properties.

Benefits of TPM Twisted Yarn

The benefits of using tpm twisted yarn are manifold. It enhances the durability and longevity of textile products, reduces maintenance costs due to its easy-care nature, and offers a hypoallergenic option for sensitive skin. For businesses, it translates to satisfied customers and repeat business, as the end products stand the test of time and use. The environmental aspect is also considered, as polyester can be recycled, making tpm twisted yarn a more sustainable option in the long run.

How to Use and Maintain TPM Twisted Yarn

Effectively using tpm twisted yarn involves understanding its capabilities and limitations. When knitting or weaving, tension settings should be adjusted to accommodate the yarn's strength and elasticity. For maintenance, it is recommended to store the yarn away from direct sunlight and in a moisture-controlled environment to preserve its quality. Cleaning should be done with mild detergents, and the yarn should be dried away from heat sources to prevent damage. Proper handling during the manufacturing process is also crucial to prevent any unnecessary wear and tear.

Target Audience and Meeting Needs

The target audience for tpm twisted yarn includes textile manufacturers, fashion designers, and industrial product developers. The yarn meets the needs of these diverse groups by offering a product that is not only versatile in its applications but also consistent in quality. Whether it is for creating durable workwear or luxurious fashion items, tpm twisted yarn provides the performance and aesthetic qualities that professionals seek. It is also favored by those in the medical textiles industry, where the yarn's hypoallergenic properties are essential.

What are the benefits of using tpm twisted yarn in textile production?

The use of tpm twisted yarn in textile production brings numerous benefits, including improved fabric strength, better dimensional stability, and enhanced visual appeal of the finished product. Its versatility allows for a wide range of textures and patterns, making it a preferred choice for innovative textile applications.

How does the twist level of tpm yarn affect the final product?

The twist level of tpm yarn directly impacts the final product's durability, feel, and appearance. Higher twists per meter result in stronger yarns that are less prone to fraying, while lower twists offer a softer texture. Manufacturers must choose the appropriate twist level to meet the desired quality and functionality of the textile.

Can tpm twisted yarn be customized for specific industrial applications?

Yes, tpm twisted yarn can be customized to meet specific industrial requirements. Alibaba.com connects buyers with suppliers who can provide yarns with tailored properties such as color, tenacity, and moisture absorption, ensuring that the yarn meets the precise needs of the intended application.