Understanding Transformer Lamination Machines

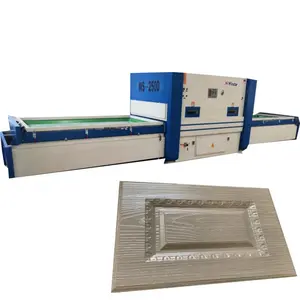

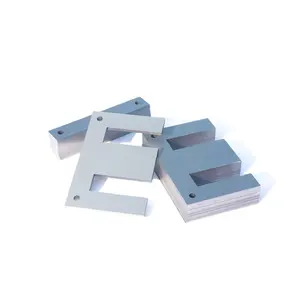

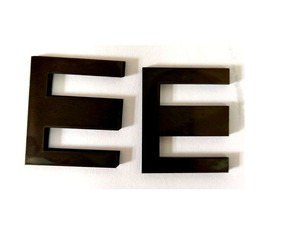

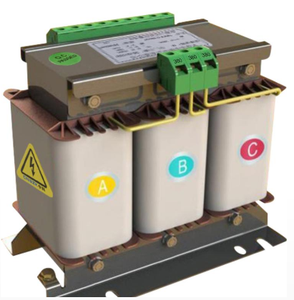

Transformer lamination machines are essential in the electrical industry, playing a pivotal role in the manufacturing of transformers. These machines are designed to cut and shape laminated steel cores, which are crucial for the efficient operation of transformers. The core's quality directly impacts the transformer's performance, making the lamination process vital.

Types and Applications

There are various types of transformer lamination machines, each serving a specific purpose. Some are tailored for small transformers, while others cater to large-scale production. The applications of these machines span across different sectors, including power transmission, electronics, and renewable energy industries, where they are used to produce transformer cores with precision.

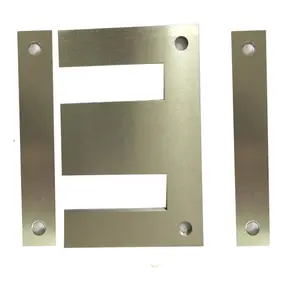

Features and Materials

Transformer core cutting machines are known for their robust construction and precision. Typically, these machines are built with durable materials like high-grade steel and incorporate advanced technology to ensure accurate lamination cutting. The materials used in the machine construction are chosen for their durability and resistance to wear, ensuring longevity and consistent performance.

Advantages of Modern Lamination Machines

Modern transformer lamination machines offer a range of advantages. They are designed for efficiency, with features that reduce waste and energy consumption. The precision of core cutting machines ensures that the lamination fits perfectly, which is crucial for the transformer's energy efficiency. Additionally, the automation capabilities of these machines minimize the need for manual intervention, leading to a more streamlined production process.

Choosing the Right Machine

Selecting the right transformer lamination machine involves considering several factors, such as the intended application, desired output, and material compatibility. Prospective buyers should assess the core lamination technology and the machine's adaptability to different production environments. It's also important to consider the machine's footprint and energy requirements to ensure it fits within the operational infrastructure.

Procuring on Alibaba.com

Alibaba.com simplifies the procurement of transformer lamination machines by offering a platform where buyers can connect with suppliers globally. The platform provides a diverse array of transformer lamination machine options, enabling businesses to find machines that meet their specific needs. With detailed product descriptions and specifications, buyers can make informed decisions without the pressure of immediate purchase commitments.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4