Trough Type Cable Trays: An Overview

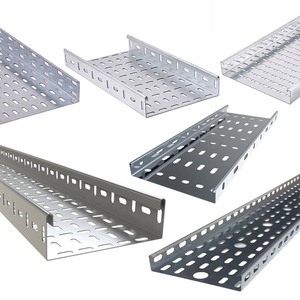

Trough type cable trays are integral components in modern cable management systems, designed to support insulated electric cables used for power distribution, control, and communication. These trays are characterized by their solid bottom, which provides a robust platform for cables and offers protection against various environmental factors.

Design and Material Considerations

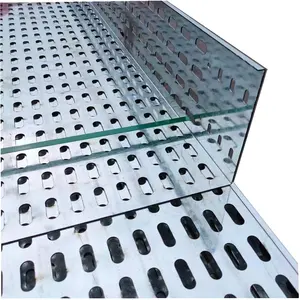

The design of trough type cable trays is focused on durability and protection. Typically constructed from materials like galvanized steel, stainless steel, or aluminum, these trays can withstand harsh conditions while preventing the accumulation of dust and debris. The choice of material often depends on the specific requirements of the environment, such as resistance to corrosion or electrical conductivity.

Applications and Uses

Trough type cable trays are versatile and can be utilized in diverse settings, from commercial buildings to industrial facilities. Their primary function is to securely route and support cables, ensuring an organized and accessible cable network. These trays are particularly useful in areas where shielding from potential hazards is necessary, as their solid construction provides an extra layer of safety.

Features and Advantages

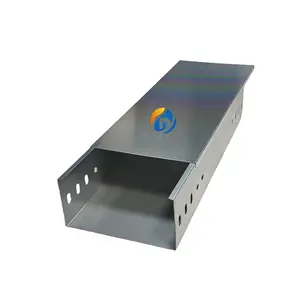

One of the key features of trough type cable trays is their ease of access. The top of the tray can be covered with a removable or hinged cover, which simplifies the process of cable placement and maintenance. The solid construction also minimizes the ingress of foreign objects, protecting the cables from damage. Additionally, the trough design inherently guards against electromagnetic interference, making it suitable for sensitive applications.

Customization and Compatibility

Flexibility in customization allows trough type cable trays to meet the specific needs of various projects. They can be cut to length, fitted with dividers, and accessorized with bends, tees, and cross units for directional changes. This adaptability ensures that they can be integrated into any cable management scheme, providing a seamless and efficient layout.

Selection and Integration

Selecting the appropriate trough type cable trays involves considering factors such as load capacity, environmental conditions, and the type of cables being used. Integration into an existing system requires careful planning to ensure compatibility and compliance with safety standards. While the trays themselves are a crucial component, the overall effectiveness of a cable management system also relies on proper installation and use of complementary accessories.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4