Introduction to Ultrasonic Ice Cream Homogenizers

The ultrasonic ice cream homogenizer is a pivotal piece of equipment in the dairy and food processing industry. This innovative technology is designed to enhance the consistency and stability of ice cream by applying ultrasonic waves to the mixture, resulting in a uniform product with a refined texture. The application of ultrasonics in homogenization processes marks a significant advancement from traditional methods, offering efficiency and consistency in product quality.

Types and Applications

There are various types of ultrasonic homogenizers tailored to meet different production needs. From small-scale units for boutique ice cream shops to industrial-grade machines for large-scale production, the versatility of these homogenizers is vast. Their applications extend beyond ice cream, serving essential roles in the homogenization of dairy products, the emulsification of cosmetics, and the dispersion of pharmaceuticals, showcasing their multifaceted utility.

Features and Materials

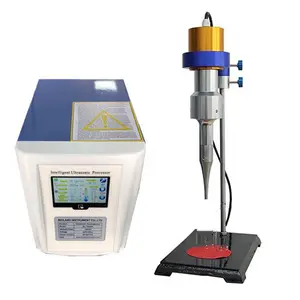

An ultrasonic homogenizer for ice cream is equipped with features that promote ease of use and efficiency. Typically constructed from robust stainless steel, these machines are designed for longevity and compliance with food safety standards. Advanced models boast digital controls for precise manipulation of ultrasonic intensity and duration, ensuring optimal homogenization for every batch.

Advantages of Ultrasonic Homogenization

The use of ultrasonic technology in homogenizers presents numerous advantages. It provides a non-thermal method of processing, which is crucial in preserving the nutritional and sensory qualities of ice cream. The technology also contributes to a reduction in particle size, leading to a smoother and creamier product. Moreover, the efficiency of ultrasonic homogenizers can lead to reduced processing times and energy consumption.

Maintenance and Operation

Maintaining an ultrasonic homogenizer is straightforward, requiring regular cleaning and occasional servicing to ensure its longevity and performance. Operators of these machines should receive proper training to utilize the equipment effectively, maximizing the potential of the homogenizer to produce a consistently high-quality product.

Choosing the Right Ultrasonic Homogenizer

Selecting the appropriate ultrasonic ice cream homogenizer is crucial for any business in the food processing industry. Factors such as capacity, frequency range, and material compatibility should be considered to find a unit that aligns with specific production requirements. Alibaba.com hosts a diverse array of homogenizers, facilitating the connection between buyers and experienced suppliers, ensuring a variety of choices without the direct endorsement of any single brand.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4