Popular in your industry

Related Searches:

Top categories

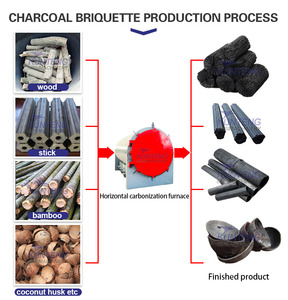

About wood charcoal machinery

Wood charcoal machinery is a broad term that encompasses various equipment used in the wood charcoal making machine process. These machines are designed to transform wood biomass into high-quality charcoal for diverse applications. The primary stages of wood charcoal production include carbonization, cooling, crushing, and packaging. Carbonization involves heating the wood material in an oxygen-limited environment to remove volatile compounds and moisture, leaving behind the carbonized structure. The cooling step is crucial to stabilize the charcoal and prevent it from combusting. After cooling, the charcoal is broken down into smaller, more manageable pieces in the crushing stage. Finally, the charcoal is packaged for storage, transportation, or sale to end users. Each stage in the wood charcoal production process requires specialized equipment to ensure efficiency and quality.

Types of wood charcoal machinery

Several types of wood charcoal machinery are available to meet the diverse needs of charcoal producers. Traditional methods of charcoal production involve simple kilns or pits, while modern technologies have introduced advanced wood coal making machines that streamline the process. The traditional methods involve the use of earth or brick kilns, which are relatively inexpensive but labor-intensive. Modern technologies have led to the development of more efficient and automated equipment, such as rotary carbonization furnaces, continuous carbonization furnaces, and coal pellet making machines. These machines offer higher production capacities, improved control over the carbonization process, and reduced emissions. The choice of wood charcoal machinery depends on factors such as production scale, available resources, and desired charcoal quality.

Benefits of wood charcoal machinery

The use of wood charcoal machinery offers several benefits. First, it provides a more controlled and efficient carbonization process, leading to higher charcoal yields and consistent quality. Second, these machines are designed to minimize energy consumption and reduce emissions, making the wood charcoal production process more environmentally friendly. Third, the automation and advanced features of modern wood charcoal machinery improve operational efficiency and reduce the labor requirements. This not only increases productivity but also ensures a safer working environment for operators. Lastly, the versatility of wood charcoal machinery allows for the production of various charcoal products, including briquettes and lump charcoal, catering to different market demands.

Applications of wood charcoal machinery

Wood charcoal machinery finds applications in various industries and settings where high-quality charcoal is in demand. In the food industry, coal pellet machines are used to produce charcoal for grilling, smoking, and barbecuing. The consistent quality and clean-burning properties of this charcoal enhance the flavor of the cooked food. In the metallurgical industry, charcoal is utilized in the production of iron and steel. The wood charcoal machinery ensures the production of high-purity charcoal, which serves as a reducing agent in metal smelting processes. The agricultural sector uses charcoal as a soil amendment to improve fertility and sequester carbon. Charcoal production machines play a vital role in creating biochar for agricultural applications. Furthermore, in the pharmaceutical and cosmetic industries, activated charcoal is produced using specialized wood charcoal machinery. This activated charcoal is utilized for its adsorption properties in various medical and skincare products.