Popular in your industry

Related Searches:

Top categories

About wood plastic synthetic plank

Exploring Wood Plastic Synthetic Planks

Wood plastic synthetic planks represent a versatile and sustainable category within the construction and design industries. These composite materials combine the aesthetic appeal of wood with the durability and maintenance ease of plastics, offering a practical solution for various applications.

Composition and Manufacturing

Wood plastic composite (WPC) planks are manufactured through a process that mixes wood fibers or wood flour with thermoplastics, including PE, PP, PVC, or PLA. The inclusion of additives such as colorants, UV stabilizers, and coupling agents enhances the performance characteristics of these planks. This unique composition results in a material that stands up to outdoor elements better than traditional wood.

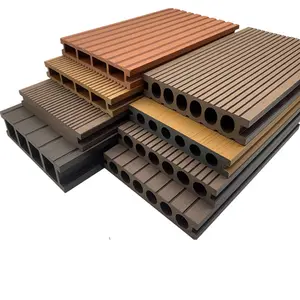

Types and Features

The market offers a diverse range of wood plastic composite decking options, catering to different aesthetic preferences and functional requirements. These planks come in various thicknesses, commonly from 18mm and above, with surface treatments such as brushing to emulate the texture of natural wood. The design versatility of WPC decking allows it to suit traditional, contemporary, and European styles, making it a suitable choice for a multitude of project designs.

Applications and Advantages

Wood plastic synthetic planks are primarily used in decking applications, but their use extends to plastic flooring and engineered flooring solutions. Their adaptability makes them an ideal choice for comprehensive project solutions, including residential, commercial, and public spaces. The benefits of using WPC planks include resistance to weathering, decay, and pests, which are common issues with pure wood products. Additionally, these planks require minimal maintenance, making them a cost-effective and long-lasting material choice.

Sustainability and Environmental Impact

Sustainability is a significant advantage of wood plastic synthetic planks. The wood used is often recycled wood waste, and the plastic component can also be sourced from recycled materials, contributing to a reduction in waste and the use of virgin materials. The durability of WPC materials also means less frequent replacement and, consequently, less waste over time.

Choosing the Right Plank for Your Project

Selecting the appropriate wood plastic composite plank for a project involves considering the specific design and functional needs of the space. While Alibaba.com does not endorse or guarantee the products, the platform facilitates access to a broad selection of suppliers offering a variety of WPC products. It is essential to review the specifications of each product, such as dimensions, design options, and material composition, to ensure the right fit for your project requirements.